Robust dual-pipe design handles heavy solids effortlessly. Fully submersible, corrosion-resistant construction ensures reliable wastewater drainage in harsh environments.

MOQ:

1Package:

CustomziedColor:

CustomziedMaterial:

Cast iron/Stainless steelWorking Temp:

≤60 ℃

Product Overview

The YW-type clog-free submersible sewage pump integrates advanced technology to handle solid particles and long-fiber waste efficiently. Its unique single/double-channel impeller and optimized volute design ensure high flow capacity and energy efficiency. The pump features anti-clogging performance, vibration-free operation (due to balanced impellers), and durable mechanical seals. Rigorously tested to meet industry standards, it delivers reliable performance and has gained strong market recognition for its durability and efficiency in wastewater applications.

Product Features

The YW-type submersible sewage pump features an advanced anti-clogging design with large flow channels that can efficiently handle fibers up to 5 times the pump's diameter and solid particles up to 50% of its diameter. Its optimized hydraulic design and properly matched motor ensure high efficiency and significant energy savings. The pump is equipped with durable tungsten carbide dual-series mechanical seals, enabling reliable continuous operation for over 8,000 hours. With its compact structure, lightweight design, and easy installation features, this pump offers both superior performance and convenient maintenance.

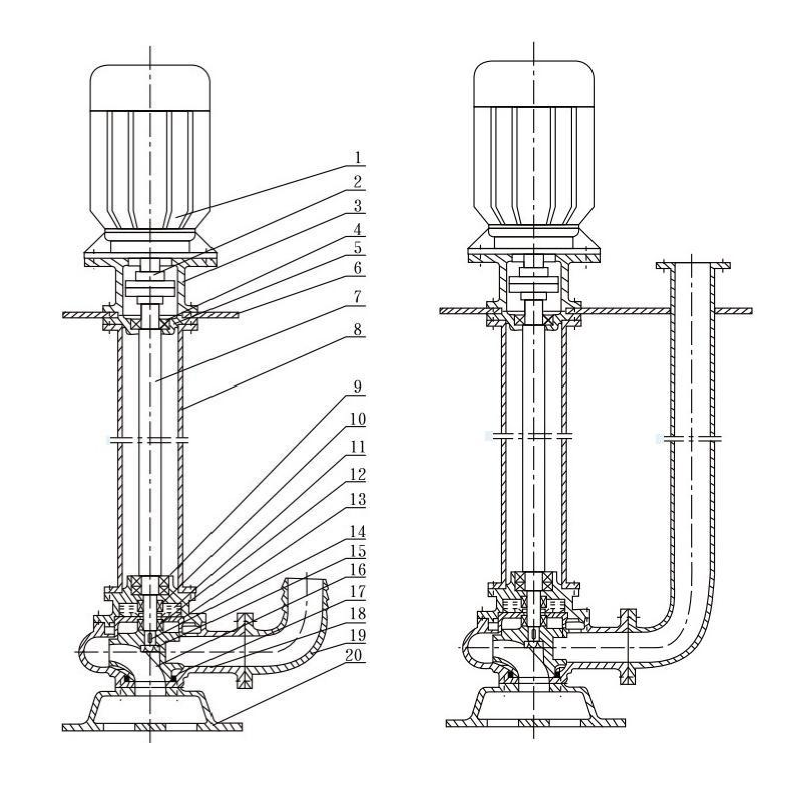

Structural Description

1.Medium Temperature ≤60℃, Specific gravity: 1.0~1.3kg/dm³, PH range: 5~9.

2.Operating Conditions: The pump must operate within the specified head range to prevent motor overload. For full-range head operation, please indicate when ordering to allow manufacturer customization.

3.Electrical Parameters: During operation, the motor current shall not exceed its rated current.

4.Customization Note: For special temperature/media requirements, please specify detailed medium characteristics when ordering to facilitate manufacturer production.

| 1 | Motor |

| 2 | Coupling |

| 3 | Motor Mount |

| 4 | Upper Bearing |

| 5 | Upper Bearing Housing |

| 6 | Mounting Flange |

| 7 | Extension Shaft |

| 8 | Support Tube |

| 9 | Lower Bearing |

| 10 | Upper Mechanical Seal |

| 11 | Oil Chamber |

| 12 | Mechanical Seal |

| 13 | Rear Cover Plate |

| 14 | Key |

| 15 | Impeller Nut |

| 16 | Impeller |

| 17 | Seal Ring |

| 18 | Pump Casing |

| 19 | Discharge Pipe |

| 20 | Base Plate |

Application scenarios