The axial-flow pump belongs to the category of pumps. It features an impeller that rotates around the axis. This impeller pushes water forward in the axial direction. As a result, the axial-flow pump is well-suited for applications involving large flow rates and low heads, such as irrigation and drainage systems.

Payment:

TT L/C PayPal Westunion MoneygramProduct Origin:

China, Anhui provinceColor:

customizedShipping Port:

shanghaiLead Time:

1 monthMOQ:

1Package:

CustomziedColor:

CustomziedMaterial:

SteelWorking Temp:

Fluoroplastic material: -20 to 120 ℃;Graphite material:-20 to 80 ℃ .Working Pressure:

1.6 MPa

Product review

The THZW axial flow pump is a single-stage single-suction cantilever centrifugal pump that has been meticulously designed in accordance with the GB/T13008 standard. It incorporates the hydraulic model of CDF, thereby qualifying as a highly efficient and energy-saving product.

To enhance its performance and reliability, the shaft diameter of this pump has been deliberately thickened. This design modification not only adds strength but also contributes to the overall stability of the pump. Additionally, the cantilever ratio has been shortened, effectively eliminating the common disadvantages typically associated with chemical pumps.

As a result of these improvements, the THZW axial flow pump offers enhanced stability during operation. This, in turn, leads to a significant reduction in both maintenance and operation costs, making it a cost-effective and dependable choice for various applications.

Product advantages

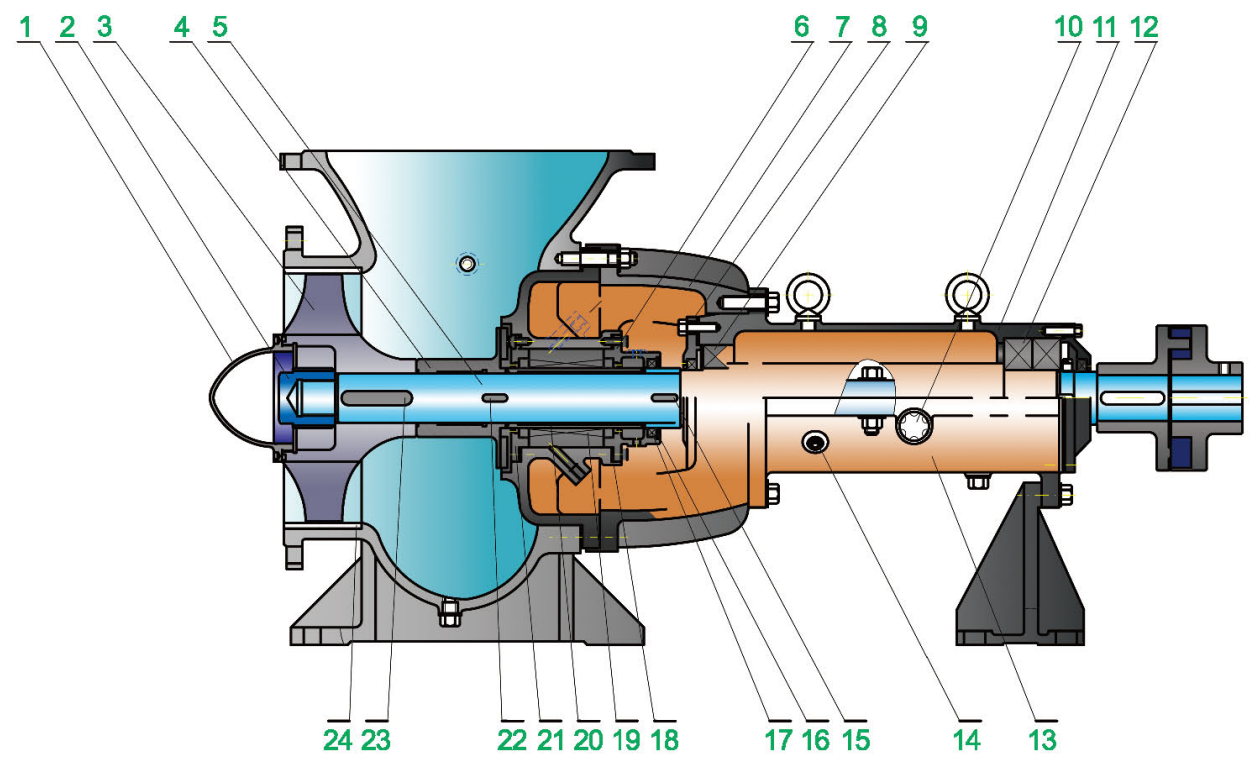

Material List

| Part | Material | Part | Material | Part | Material |

| ① Sealing cap | 304/316/316L | ⑨ Bearing | GCR15 | ⑰ Axle sleeve | 304/316/316L |

| ②Impeller nut | 304/316/316L | ⑩ Bolt | A3 | ⑱ Seal sleeve | 304/316/316L |

| ③ Impeller | 304/316/316L | ⑪ Bearing upper cover | HT200 | ⑲ Seal assembly | 304/316/316L |

| ④ Expeller | 304/316/316L | ⑫ Bearing | GCR15 | ⑳ Inner six angle screw | 304/316/316L |

| ⑤ Pump shaft | 2Cr13 | ⑬ Bearing box lower cover | HT200 | ㉑ Bolt | 304/316/316L |

| ⑥ Rear ring seat | 304/316/316L | ⑭ Bolt | A3 | ㉒ Intermediate plate | 304/316/316L |

| ⑦ pump bracket | HT200 | ⑮ Oil seal | Oil resistant rubber | ||

| ⑧ Bearing cover | HT200 | ⑯ Flat pad | A3 |

Structural diagram

Performance range

Design pressure : 1.6MPa; Flow :~18000m³/ h ; Lift :~4m; Caliber :~1200mm;Power :1.1-400kw;

Applicable temperature : ① Ofluoroplastic material :-20~120℃( acid - base medium of any concentration );

② Graphite material :-20~80℃( dilute acid and alkali medium ).

Product application

It is extensively utilized for transporting corrosive liquids within the production processes of numerous industries. These include the petroleum industry, chemical engineering, alkali production, smelting, rare earth extraction, pesticide manufacturing, dye production, pharmaceuticals, papermaking, electroplating, electrolysis, radio-related fields, chemical foil production, and the national defense industry, among others.

Others