Using corrosion-resistant graphite, the Water Jacket Graphite Hydrogen Chloride Synthesis Furnace can produce HCl efficiently, thus ensuring precise temperature control and optimal reaction conditions.

Payment:

TT L/C PayPal Westunion MoneygramProduct Origin:

China, Anhui provinceShipping Port:

ShanghaiLead Time:

1 MonthMOQ:

1Package:

Wooden caseColor:

CustomziedMaterial:

GraphiteWorking Temp:

Export≤45℃,Graphite wall≤170℃

Product review

It is composed of a steel shell, a graphite furnace cover, a synthetic cylinder, and a furnace bottom. Compared with the steel shell furnace, it features the following:

1. Long service life (generally over 10 years).

2. High purity of the product acid.

3. Favorable working conditions, with convenient control and management.

Product advantages

The Water Jacket Graphite Hydrogen Chloride Synthesis Furnace offers excellent corrosion resistance, efficient heat transfer, precise temperature control, durability, and reliable performance in harsh chemical environments.

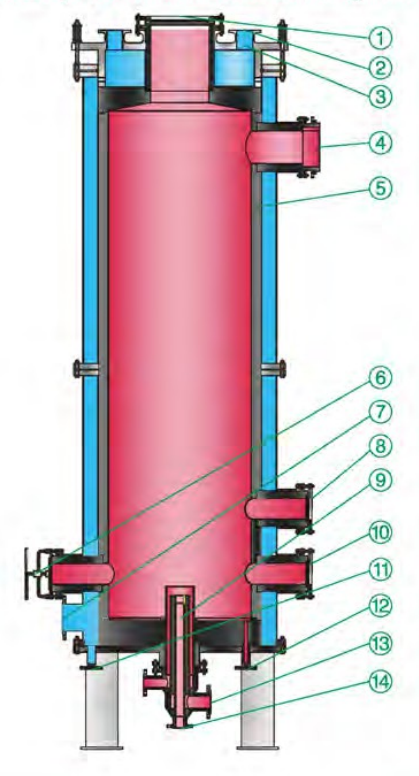

Structural diagram

| Parts details | |

| 1 | Explosion proof port |

| 2 | Cooling water outlet |

| 3 | Cooling outlet |

| 4 | HCl outlet |

| 5 | Graphite synthetic cylinder |

| 6 | Furnace door |

| 7 | Cooling water inlet |

| 8 | Mirror |

| 9 | Three sets of quartz glass burner |

| 10 | Mirror |

| 11 | Drain port |

| 12 | Acid outlet |

| 13 | Chlorine inlet |

| 14 | Hydrogen inlet |

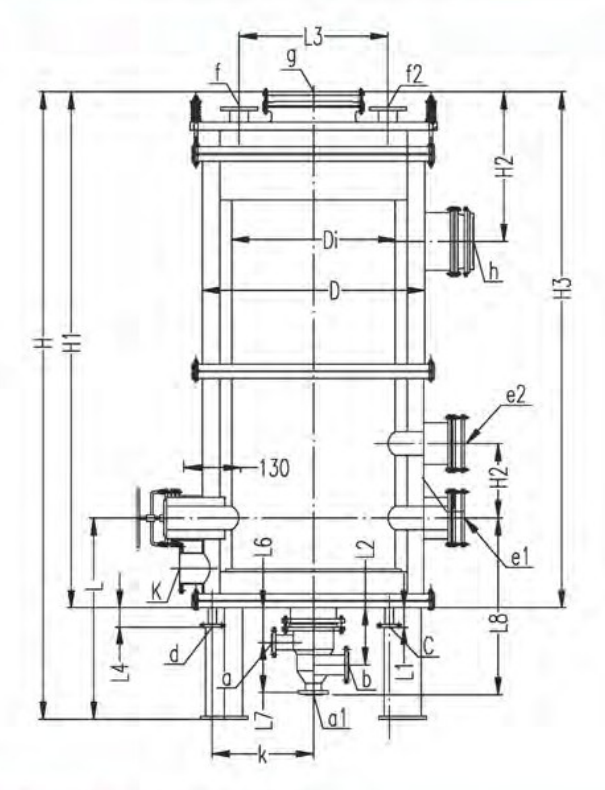

Drawing Specification Table for Tube

| Symbol | a | b | c | d | e | f | g | h | k |

| Specifications | DN/D1 | DN/D1 | DN | DN | DN | DN | DN | DN/D1 | DN |

| SSL-300 | 40/125 | 40/125 | 20 | 50 | 125 | 80 | 250 | 75/180 | 40 |

| SSL-400 | 55/145 | 55/145 | 20 | 50 | 125 | 100 | 250 | 100/210 | 50 |

| SSL-500 | 70/180 | 70/180 | 20 | 50 | 125 | 125 | 250 | 125/240 | 65 |

| SSL-600 | 84/210 | 84/210 | 20 | 50 | 125 | 150 | 400 | 150/295 | 80 |

| SSL-700 | 100/210 | 100/210 | 20 | 50 | 125 | 200 | 400 | 200/350 | 100 |

| SSL-800 | 115/240 | 115/240 | 20 | 50 | 125 | 200 | 400 | 200/350 | 100 |

| SSL-900 | 115/240 | 115/240 | 20 | 50 | 125 | 200 | 400 | 250/400 | 125 |

| SSL-1000 | 115/240 | 115/240 | 20 | 50 | 125 | 200 | 400 | 250/400 | 150 |

| Nozzle connection standard |

HG 20593 | HG 20593 | - | HG 20593 | - | HG 20593 | - | - | HG 20593 |

| Pressure level MPa |

1.0 | 1.0 | - | 1.0 | - | 1.0 | - | 1.0 | 1.0 |

| Nozzle usage | Hydrogen inlet | Hydrogen inlet | Acid outlet | Exhaust port | Mirror port | Water outet | Explosion proof port | Hydrogenated hydrogen outlet | Cooling water inlet |

Others