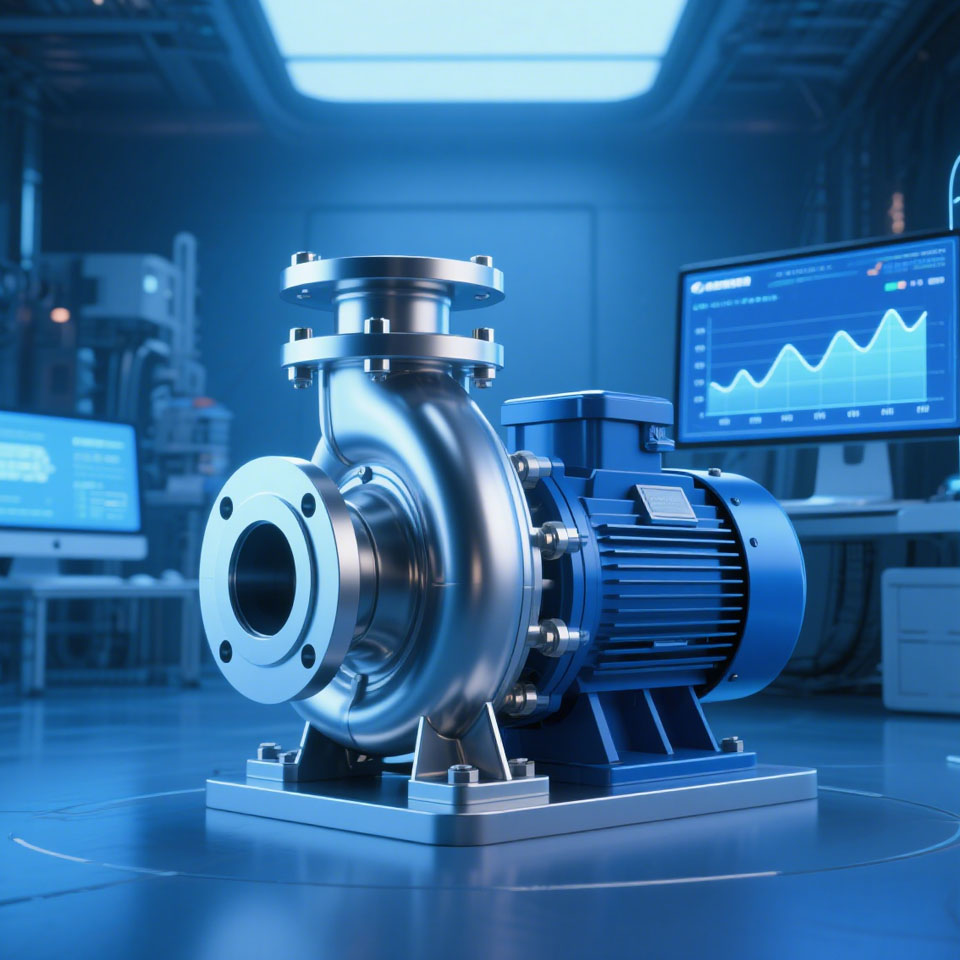

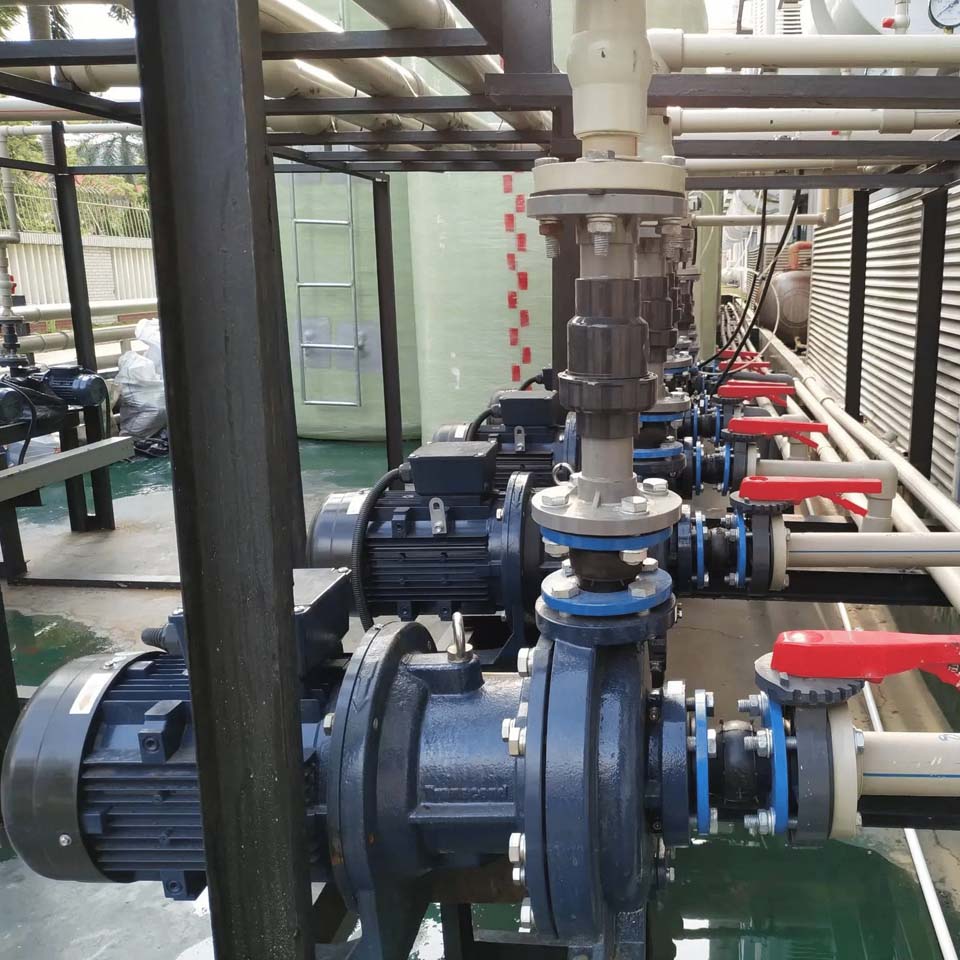

A Quick Look at Chemical Centrifugal Pumps Chemical centrifugal pumps are workhorses in the chemical biz because they're tough, pump water consistently, run smoothly, aren't too loud, easy to tweak, and do their job well. Basically, when the pump is full of water and the impeller spins, it creates a force that shoots the water from the impeller into the pump's outer shell. This drops the pressure in the middle of the impeller lower than the pressure in the pipe that pulls water in. Because of this difference, water keeps flowing from the source into the impeller, letting the pump keep sucking in and pushing out water. Since more industries need these pumps, it's worth getting into the nitty-gritty details. Anhui Shengshi Datang's gonna walk you through 20 Q&As to clear up some of the mystery surrounding them. Let's follow Anhui Shengshi Datang to take a look. What Makes Them Special? These pumps are popular because they can handle wear and tear and keep the water flowing at a steady rate. They're good at dealing with what chemical processes throw at them; they don't rust easily, can take the heat (or the cold), resist damage, and can move liquids that are close to changing state. The Technical Stuff a. What They Are and How They're Sorted Chemical centrifugal pumps use a spinning impeller to create force. They can be vane pumps, positive displacement pumps, etc. Vane pumps use the spinning impeller to give liquids a boost, while positive displacement pumps move liquids by changing the size of a chamber. Then you've got special ones like electromagnetic pumps (which use electricity to move liquids) and jet/airlift pumps that use fluid energy to get the job done. b. What's Good About Them, and Key Numbers Centrifugal pumps can move a lot of liquid quickly. They are easy to keep running. The most important things to consider are how efficient they are and how much power they use. They keep things flowing smoothly and come in small packages, so they don't take up too much space. They're simple, with not many parts that can break, and they don't need a lot of upkeep. They're easy to adjust and don't need oil inside, so they don't mess with the liquid they're moving. c. Where Energy Gets Lost, and How Efficient They Are The main ways energy get lost are through whirlpools, resistance, and impacts. Efficiency boils down to how much power you get out compared to what you put in. Liquid loses energy because of friction inside the pump This energy turns into heat or other stuff. These losses mainly come from whirlpools, resistance, and impacts, which make the pump less efficient than it could be. Pump efficiency is the ratio of useable power versus what goes in. d. Speed and Power How fast it spins impacts flow and pressure. Power is usually measured in watts or kilowatts. How fast the rotor is spinning is speed. Power is how much energy prime mover gives to the pump. e. Pressure and Flow If you tweak the speed, the flow and pressure change, too...

Read More English

English français

français русский

русский español

español português

português العربية

العربية ไทย

ไทย Tiếng Việt

Tiếng Việt Indonesia

Indonesia  中文

中文

IPv6 network supported

IPv6 network supported