The TY series stainless steel submersible pump is constructed of stainless steel, endowing it with excellent corrosion resistance. It boasts high performance and reliability, making it an ideal choice for liquid transfer in a wide range of applications.

MOQ:

1Package:

CustomziedColor:

CustomziedMaterial:

SteelWorking Temp:

Fluoroplastic material:-20 to 200 ℃; Engineering plastic material:-20 to 80 ℃ ;Stainless steel material:-20 to 200 ℃ .Working Pressure:

1.6 MPa

Product review

The TY submerged pump (mag drive submersible pump) is designed in accordance with national standards. Taking into account the working conditions of users, its submersion depth can vary from 1 to 8 meters. The main body of the pump is situated within the liquid.

This pump(chemical resistant submersible pump)offers a multitude of advantages. It has a wide range of corrosion resistance, ensuring durability in various environments. Its high efficiency makes it a reliable choice for liquid handling tasks. The shaft connection structure is both safe and reliable, minimizing the risk of malfunctions. Additionally, it is easy to disassemble, facilitating maintenance and repair work.

One particularly notable feature is that it can operate without the requirement for liquid filling. During pump operation, the axial force and radial force are respectively supported by rolling bearings and sliding bearings. This design ensures that the pump runs smoothly and quietly, providing a stable and efficient performance.

Product advantages

1. The flow passage components, such as the pump casing, pump cover, and impeller, are manufactured using high-quality stainless steel, fluoroplastic, and engineering plastic.

2. This pump(chemical resistant submersible pump)features no shaft seal. The bearing and shaft sleeve are constructed from materials like graphite and tetrafluoro, which effectively guarantee the pump's service life.

3. It can function without the necessity of liquid filling. The submersion depth has the potential to reach up to 8 m. Additionally, there is no need for independent lubrication and cooling water, thus reducing energy consumption.

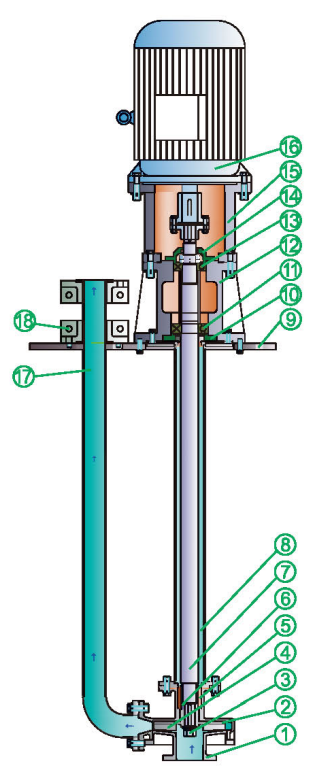

Material List

| Part | Material | Part | Material |

| ① Pump casing | 304/316/316L | ⑩ Front gland of bearing | HT200 |

| ② Pump cover | 304/316/316L | ⑪ Front bearing | Gcr15 |

| ③ Impeller nut | 304/316/316L | ⑫ Bearing box | HT200 |

| ④ Impeller | 304/316/316L | ⑬ Back bearing | Gcr15 |

| ⑤ Shaft sleeve | GRAPHITE/SIC | ⑭ Back gland of bearing | HT200 |

| ⑥ liner bushing | PTFE | ⑮ Bracket | HT200 |

| ⑦ Main shaft | 304/316/316L | ⑯ Motor | Customized |

| ⑧ Main pipeline | 304/316/316L | ⑰ Drainpipe | 304/316/316L |

| ⑨ Square plate | A3 | ⑱ Outlet flange | HT200 |

Structural diagram

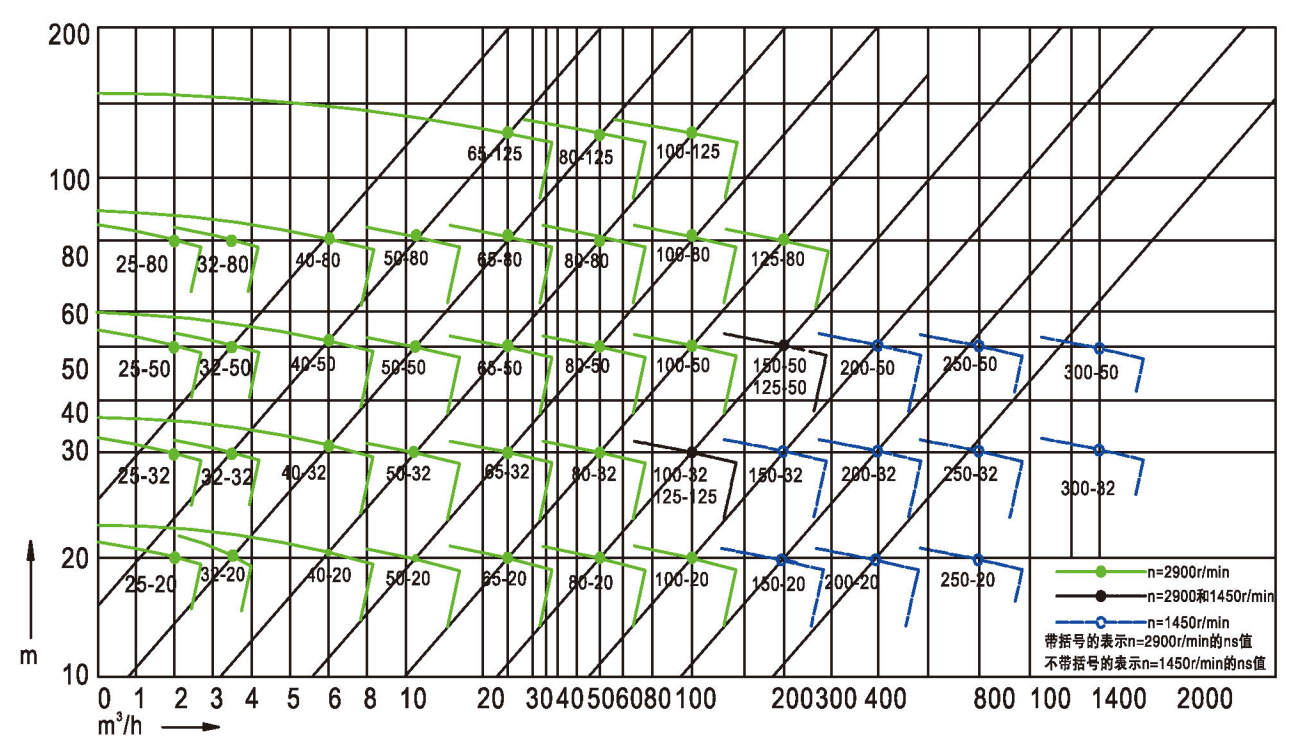

Performance range

Design pressure :1.6MPa; Flow :1.5~1000m³/h; Lift :15~125m; Power :2.2~185kw.

Applicable temperature : ① Ofluoroplastic material :-20~120℃( acid-base medium of any concentration );

② Engineering plastic material :-20~80℃( dilute acid and alkali medium );

③ Stainless steel material :-20~200℃( alkali medium ).

Product application

It is extensively utilized in various production processes, including those in the petroleum industry, chemical engineering, alkali production, smelting, rare earth extraction, pesticide manufacturing, dye production, pharmaceuticals, papermaking, electroplating, electrolysis, and radio-related fields, for the transportation of highly corrosive liquids.

Others