The FB single - stage single - suction cantilever corrosion - resistant centrifugal pump is engineered with precision. It has high durability and excels in handling corrosive liquids, being a reliable fluid - handling choice.

MOQ:

1Package:

CustomziedColor:

CustomziedMaterial:

AlloyWorking Temp:

-20℃ to 105℃

The FB pump is a single-stage, single-suction, cantilevered corrosion-resistant centrifugal pump. Our company has drawn on the characteristics of various pumps in the 1990s and adopted an advanced hydraulic model. With its novel structure and high-strength combined double-face mechanical seal, this pump features high efficiency and energy saving, a compact structure, stable performance, and reliable use.

Product Features

This pump is suitable for conveying non-solid particle-containing corrosive liquids. The temperature of the conveyed medium ranges from -20°C to 105°C, and the inlet pressure of the pump should not exceed 0.2 MPa. It is widely used in industrial sectors such as petroleum, chemical engineering, metallurgy, synthetic fibers, pharmaceuticals, food, and brewing. It can also be used for water supply and drainage in industrial and mining enterprises as well as in cities.

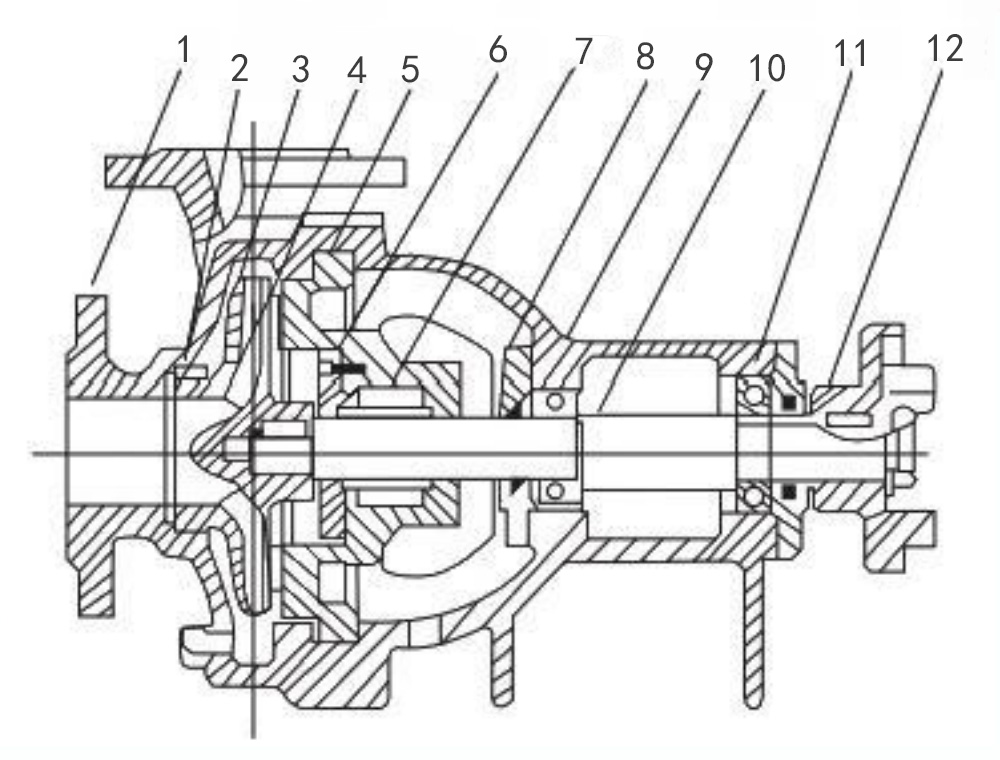

Structural Diagram

| 1 | Pump Body | 7 | Mechanical Seal |

| 2 | Seal Ring | 8 | Bearing Cover |

| 3 | Impeller | 9 | Bearing Housing |

| 4 | Impeller Nut | 10 | Pump Shaft |

| 5 | Pump Boby | 11 | Bearing |

| 6 | Seal Cover | 12 | Coupling |

Select the appropriate materials for the pump,sealing form,and pump structure based on the name,concentration of the conveyed medium (or mixture),the inlet pressure of the pump,and the degree of corrosion of the materials by the medium at the operating temperature (refer to the material corrosion resistance table and application scope).

Determine the capacity of the electric motor according to the specific gravity of the conveyed medium.

If the pump performance is properly selected by the user and the storage and usage rules specified in these instructions are followed, and the product fails to work properly due to poor manufacturing quality, our company will repair or replace the product parts for the user free of charge (except for normal wear of wearing parts and normal corrosion of parts).

If you need special materials (e.g., chromium-nickel-molybdenum-titanium steel Cr18Ni12Mo2Ti),please specify the material grade in your letter, and our company will arrange production as appropriate.

During the use of the product,if you find any quality problems,we welcome you to report them to our company regularly so that we can continuously improve and enhance the product.

Others