The CQB Stainless Steel Magnetic Drive Centrifugal Pump is reliable, corrosion-resistant, and ideal for chemical, pharmaceutical industries.

MOQ:

1Package:

CustomziedColor:

CustomziedMaterial:

Stainless SteelWorking Temp:

No More Than 100℃Working Pressure:

Max:1.6 MPa

Product Overview

The magnetic drive centrifugal pump is generally composed of an electric motor,a magnetic coupling,and a corrosion-resistant centrifugal pump.Its main feature is that it uses the magnetic coupling to transmit power,achieving completely leak-free operation.When the electric motor drives the outer magnetic steel of the magnetic coupling to rotate,the magnetic flux passes through the gap and the isolation sleeve and acts on the inner magnetic steel,enabling the pump rotor to rotate synchronously with the electric motor and transmit torque without mechanical contact.At the power input end of the pump shaft,since the liquid is sealed inside the stationary isolation sleeve,there is no dynamic seal,thus ensuring complete leak-free operation.The overcurrent components of the pump can be made of corrosion-resistant materials such as 304,304L,302,321,316,316L,UB6, CD4MCu,titanium alloy,nickel-based alloy,etc.,according to specific requirements.

Product Features

The CQB series magnetic pump is a new type of completely leak-free and corrosion-resistant pump developed by the National Joint Design Group for Magnetic Pumps.Its technical and economic indicators are comparable to those of similar foreign products in the late 1980s.The types and basic parameters of the CQB series magnetic pumps meet the requirements of the standard TB/T7742-95 "Small Magnetic Drive Centrifugal Pumps".The CQB series magnetic pumps are suitable for industries such as petroleum,chemical engineering,pharmaceuticals,metallurgy,electroplating, environmental protection,food,film and television printing and dyeing,water treatment,and national defense.They are ideal equipment for transporting various corrosive liquids,including flammable, explosive,volatile,toxic,rare and precious liquids.They are suitable for transporting liquids without hard particles,fibers,and magnetic substances,with the suction pressure not exceeding 0.2 MPa,the maximum working pressure of 1.6 MPa,the temperature not higher than 100 ℃,the density not greater than 1840 kg/m³, and the viscosity not greater than 30×10⁻⁶ ㎡/s.If the system working pressure is greater than 1.6 MPa,special design can be carried out,and the maximum system working pressure can reach 15 MPa.

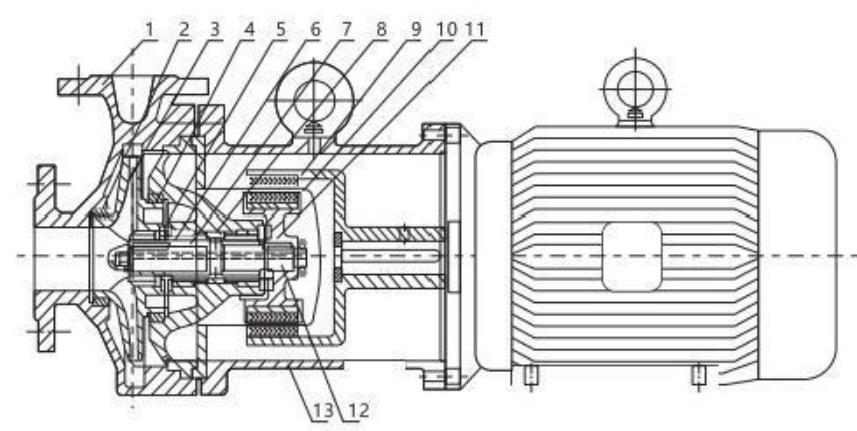

Structural Diagram

| 1 | Pump Body | 2 | Impeller |

| 3 | Static Ring | 4 | Rear Seal Ring |

| 5 | Front/Rear Thrust Ring | 6 | Bearing |

| 7 | Shaft Sleeve | 8 | Bearing Housing |

| 9 | Outer Magnetic Assembly | 10 | Isolation Sleeve |

| 11 | Inner Magnetic Assembly | 12 | Shaft |

| 13 | Connecting Frame |

Others