TC magnetic pump belongs to the new generation of centrifugal pumps. It is composed of a pump, a magnetic actuator, and a motor. Torque is transferred via magnetic force, thereby preventing leaks. This type of pump is corrosion-resistant and applicable to various industries such as the chemical and pharmaceutical industries.

Order(MOQ):

1Payment:

TT L/C PayPal Westunion MoneygramProduct Origin:

China, Anhui provinceColor:

customizedShipping Port:

shanghaiLead Time:

1 monthMOQ:

1Package:

CustomziedColor:

CustomizedMaterial:

SteelWorking Temp:

-60 to 300 ℃Working Pressure:

1.6 to 6.3 MPa

Product review

The leakless magnetic chemical pump represents a novel type of pump that operates based on the principle of modern magnetomechanics. It complies with the technical conditions for shaftless rotary power pumps (Class II) as stipulated in GB/T 25140 - 2010. Moreover, it meets the technical specification for shaftless rotary power pumps (Class II) specified in JB/T 15783 - 2002. With reference to API 685 - 20, which pertains to leakless centrifugal pumps for petroleum, heavy chemical, and other media, this pump utilizes the magnetic drive of permanent magnets to achieve contactless torque transmission.

Since the medium is sealed within the static isolation sleeve, it is possible to pump the medium without any leakage. As a result, the issue of shaft seal leakage commonly associated with mechanical drive pumps is completely eliminated.

Product advantages

1. The magnet is made of ferrite magnet, Nd-Fe-B, and samarium cobalt. It exhibits excellent magnetism, high temperature resistance, and no demagnetization.

2. The shaft sleeve and sliding bearing are fabricated from highly wear-resistant materials such as silicon carbide, graphite, and tetrafluoro. Additionally, they are equipped with lubrication grooves, which effectively ensure the service life of the pump.

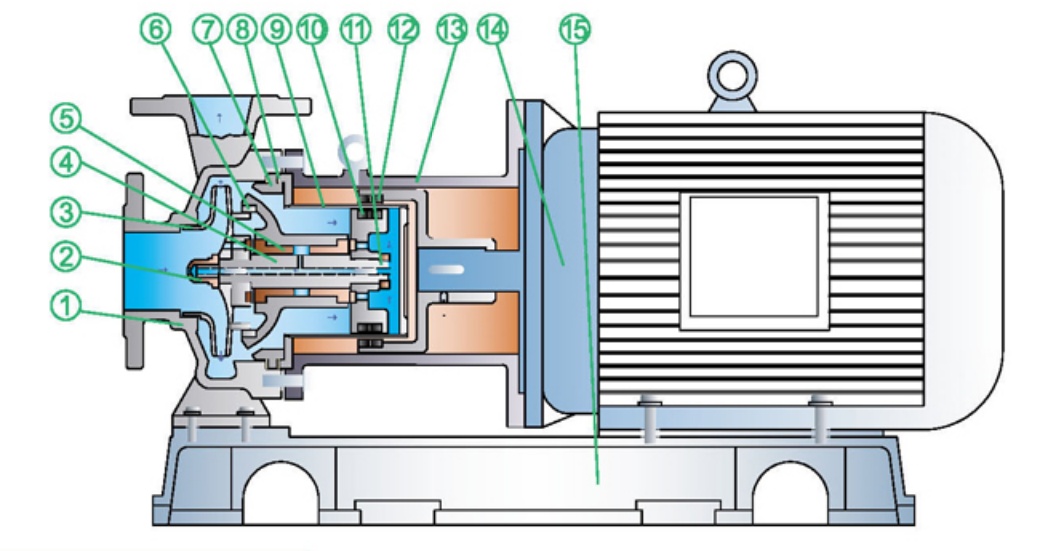

Structural diagram

| Part | Material | Part | Material | Part | Material |

| ①pump body | 304/316/316L | ⑥thrust collar | hard alloy | ⑪back nut | 304/316/316L |

| ②impeller nut | 304/316/316L | ⑦pump cover | 304/316/316L | ⑫out magnet | permanent magnet /HT200 |

| ③impeller | 304/316/316L | ⑧gasket | PTFE | ⑬connecting | HT200 |

| ④main shaft | 304/316/316L | ⑨distance sleeve | 304/316/316L | ⑭motor | As clients requested |

| ⑤shaft sleeve | GRAPHITE/SIC | ⑩inner magnet | permanent magnet /304/316/316L | ⑮base plate | HT200 |

Structural diagram

Performance Data

| Type | Rated power | Rated Flow | Rated Head | Voltage | Pump casing material | Suction |

| 25-20-125 | 2.2 | 2.5 | 20 | 380V | 304/316/316L | 25*20 |

| 25-20-160 | 3 | 2.5 | 32 | 380V | 304/316/316L | 25*20 |

| 25-20-200 | 5.5 | 2.5 | 50 | 380V | 304/316/316L | 25*20 |

| 25-20-250 | 11 | 2.5 | 80 | 380V | 304/316/316L | 25*20 |

| 32-20-125 | 2.2 | 3.2 | 20 | 380V | 304/316/316L | 32*20 |

| 32-20-160 | 3 | 3.2 | 32 | 380V | 304/316/316L | 32*20 |

| 32-20-200 | 5.5 | 3.2 | 50 | 380V | 304/316/316L | 32*20 |

| 32-20-250 | 11 | 3.2 | 80 | 380V | 304/316/316L | 32*20 |

| 40-25-125 | 2.2 | 6.3 | 20 | 380V | 304/316/316L | 40*25 |

| 40-25-160 | 3 | 6.3 | 32 | 380V | 304/316/316L | 40*25 |

| 40-25-200 | 5.5 | 6.3 | 50 | 380V | 304/316/316L | 40*25 |

| 40-25-250 | 11 | 6.3 | 80 | 380V | 304/316/316L | 40*25 |

| 50-32-125 | 3 | 12.5 | 20 | 380V | 304/316/316L | 50*32 |

| 50-32-160 | 4 | 12.5 | 32 | 380V | 304/316/316L | 50*32 |

| 50-32-200 | 7.5 | 12.5 | 50 | 380V | 304/316/316L | 50*32 |

| 50-32-250 | 15 | 12.5 | 80 | 380V | 304/316/316L | 50*32 |

| 65-50-125 | 4 | 25 | 20 | 380V | 304/316/316L | 65*50 |

| 65-50-160 | 7.5 | 25 | 32 | 380V | 304/316/316L | 65*50 |

| 65-40-200 | 15 | 25 | 50 | 380V | 304/316/316L | 65*40 |

| 65-40-250 | 18.5 | 25 | 80 | 380V | 304/316/316L | 65*40 |

| 80-65-125 | 7.5 | 50 | 20 | 380V | 304/316/316L | 80*65 |

| 80-65-160 | 15 | 50 | 32 | 380V | 304/316/316L | 80*65 |

| 80-50-200 | 18.5 | 50 | 50 | 380V | 304/316/316L | 80*50 |

| 100-80-125 | 15 | 100 | 20 | 380V | 304/316/316L | 100*80 |

| 100-80-160 | 18.5 | 100 | 32 | 380V | 304/316/316L | 100*80 |

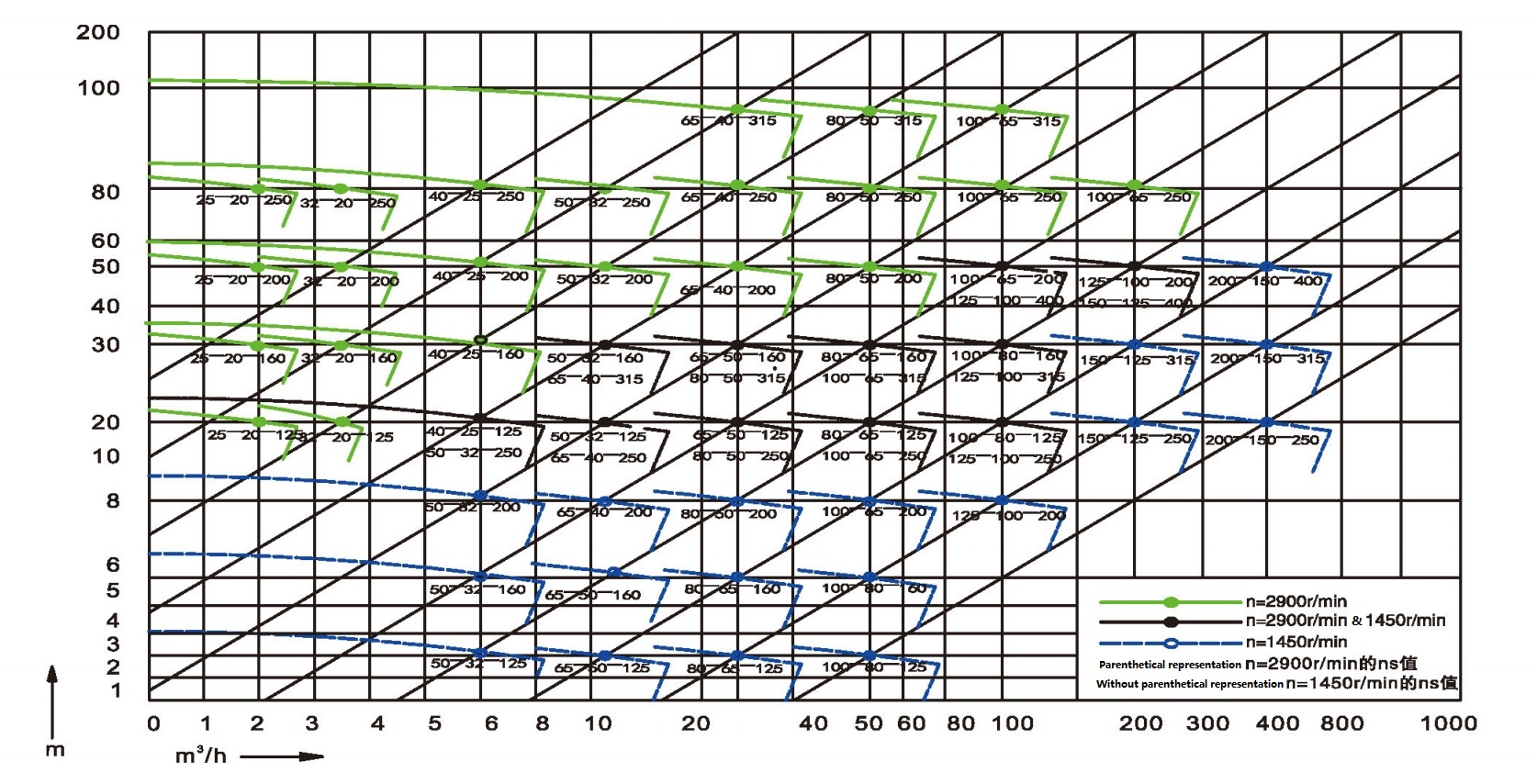

Performance range

Design pressure: 1.6 ~ 6.3MPa, Flow: 0.75 ~ 460m³/h, Lift: 5 ~ 125m, Power: 0.55 ~ 110KW

Applicable temperature: -60 ~ 300℃, new materials are adopted, and the temperature resistance can reach 450℃.

Product application

It is extensively utilized for transporting corrosive liquids during the production procedures in various industries, including petroleum, chemical engineering, alkali production, smelting, rare earth extraction, pesticide manufacturing, dye production, pharmaceuticals, papermaking, electroplating, and electrolysis.

Others