IHF pump is a single-stage, single-suction fluoroplastic alloy centrifugal pump for corrosion-resistant chemical fluid handling with high efficiency.

MOQ:

1Package:

CustomziedColor:

CustomziedMaterial:

Alloy/FluoroplasticWorking Temp:

-85℃ to 200℃

Product Overview

The IHF pump is a single-stage centrifugal pump constructed from fluoroplastic alloy, offering superior corrosion resistance against acids (sulfuric, hydrochloric, nitric), alkalis, and organic solvents. With an operating range of -85°C to 200°C, it features high mechanical strength, wear resistance, and non-toxic properties. Ideal for chemical, pharmaceutical, and industrial applications, it excels in handling aggressive media for liquid transfer, wastewater treatment, and acid dosing. Compliant with international standards, it represents cutting-edge corrosion-resistant technology.

Structure and Features

The IHF-type fluoroplastic centrifugal pump features a metal casing lined with perfluoroalkoxy (F46). The impeller and pump cover are manufactured by integrally sintering and press-molding metal inserts coated with fluoroplastic. The shaft seal adopts an externally mounted bellows mechanical seal, with the stationary ring made of 99.9% alumina ceramic or silicon carbide, and the rotating ring constructed from PTFE-filled materials or silicon carbide. Its key characteristics include an advanced and rational design, strong corrosion resistance, reliable and tight sealing performance, stable operation, low noise, and a long service life.

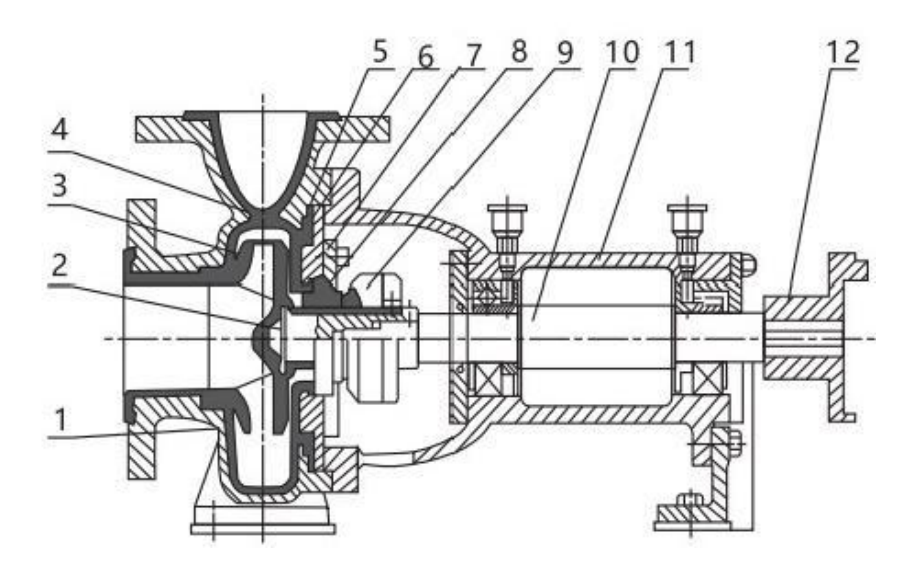

Structural diagram

| 1 | Pump body | 5 | Pump cover lining | 9 | Impeller |

| 2 | Impeller skeleton | 6 | Pump cover | 10 | Pump shaft |

| 3 | Impeller | 7 | Mechanical gland | 11 | Bearing housing |

| 4 | Pump body lining | 8 | Stationary ring | 12 | Coupling |

Others