A single-stage, single-suction cantilever centrifugal pump features a simple design with one impeller, suction on one side, and overhung mounting for efficient fluid transfer in industrial applications.

MOQ:

1Package:

CustomziedColor:

CustomziedMaterial:

Stainless Steel

Product Overview

The IH-type chemical pump is a single-stage, single-suction, cantilever centrifugal pump. Its marked rated performance points and dimensions are equivalent to the international standard ISO 2858-1975(E). As an energy-efficient product designed to replace F-type corrosion-resistant pumps, it is suitable for industries such as chemical engineering, petroleum, metallurgy, power plants, food processing, pharmaceuticals, and synthetic fibers. It is used to transport corrosive media or liquids with physical and chemical properties similar to water, within a temperature range of -20°C to 105°C.

Product Features

The pump cover is clamped between the pump body and intermediate bracket via locating shoulders. The pump features axial suction and radial discharge, with a foot-mounted design for direct base installation. The suspension components are mounted on the intermediate bracket and supported by a base bracket. An extended coupling allows rotor inspection without disconnecting piping or the motor—just remove the coupling’s intermediate piece. This is an internationally common design. Sealing options include packing or mechanical seals (ISO 3069 compliant), with alternatives like bellows or auxiliary impeller seals available if needed.

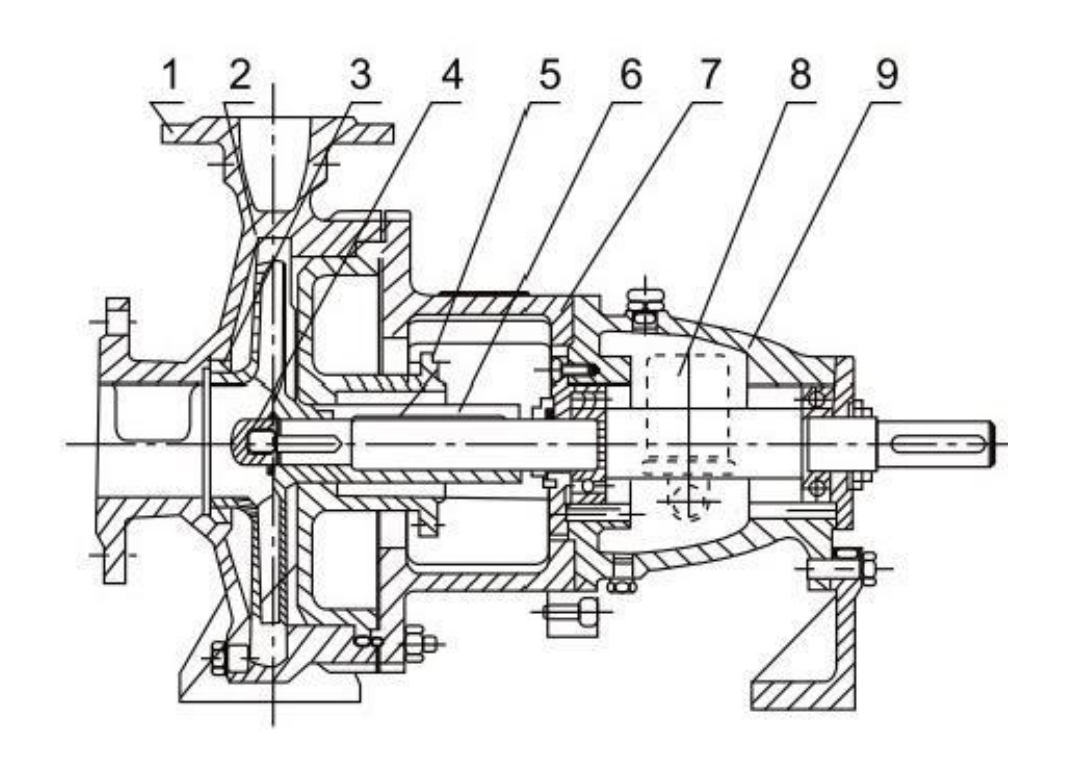

Structural Diagram

| 1 | Pump Body | 2 | Impeller |

| 3 | Sealing Ring | 4 | Impeller Nut |

| 5 | Pump Cover | 6 | Sealing Component |

| 7 | Intermediate Support | 8 | Shaft |

| 9 | Suspension Assembly |

The pump's maximum working design pressure is 1.6 MPa.

Users can select different materials for the main wetted parts of the pump according to the corrosiveness of the medium being conveyed. The materials and their codes for the main wetted parts are as follows (five options):

| Material Name | ZG1Cr18Ni9 | ZG1Cr18Ni9Ti | ZG0Cr18Ni12Mo2Ti | ZG1Cr18Ni12Mo2Ti | ZG1Cr18Mn13Mo2CuN |

| Code | 303 | 305 | 306 | 307 | 402 |

Note: In addition to the materials listed above, manufacturers can also select suitable materials for manufacturing this series of centrifugal slurry pumps according to user requirements. The selected materials and their codes should generally comply with GB2100-80.

For materials not yet assigned codes by national standards, internationally or domestically recognized material codes (such as industry or factory standards) are permitted.

Others