The G Type Sealed Single Screw Pump efficiently handles viscous fluids with sealed design, ensuring leak-proof operation and reliable performance in industrial applications.

MOQ:

1Package:

CustomziedColor:

CustomziedMaterial:

Stainless Steel/Cast Iron

Product Features

The G-type single-screw pump is an internally meshed, enclosed screw pump belonging to the category of rotary positive displacement pumps. Due to its strong adaptability to media, smooth flow, excellent suction performance, and minimal pressure pulsation, this pump can handle not only various flowable media but also highly viscous substances, media containing hard suspended or solid particles, and fibrous materials. It offers superior adjustability with a wide range, high efficiency, and is therefore widely applied across various industries such as environmental protection, marine, petroleum, pharmaceuticals, personal care, food, brewing, construction, mining, chemicals, printing, papermaking, power plants, and boilers.

Product Overview

The G-type single-screw pump is a positive displacement pump featuring a helical rotor and stator, ideal for handling viscous, abrasive, or shear-sensitive fluids. It offers smooth flow, self-priming capability, and high efficiency in industries like wastewater, oil, and chemical processing. Its robust design ensures reliable performance with minimal maintenance.

Working Principle

The single screw pump is an internally meshing rotary positive displacement pump. Its main working components are an eccentric screw (rotor) and a fixed bushing (stator). Due to the unique geometric shapes of the rotor and stator, several separate sealed cavities are formed. As the rotor rotates, the medium within each sealed cavity is transported continuously, uniformly, and at a constant volume from the suction end to the discharge end.

Thanks to these characteristics, the single screw pump is particularly suitable for the following working conditions:

1.Handling highly viscous media

2.Transporting media containing solid particles or fibers

3.Applications requiring continuous, stable pressure without periodic fluctuations

4.Operations demanding minimal agitation to avoid damaging the inherent structure of the medium

5.Low-noise environments

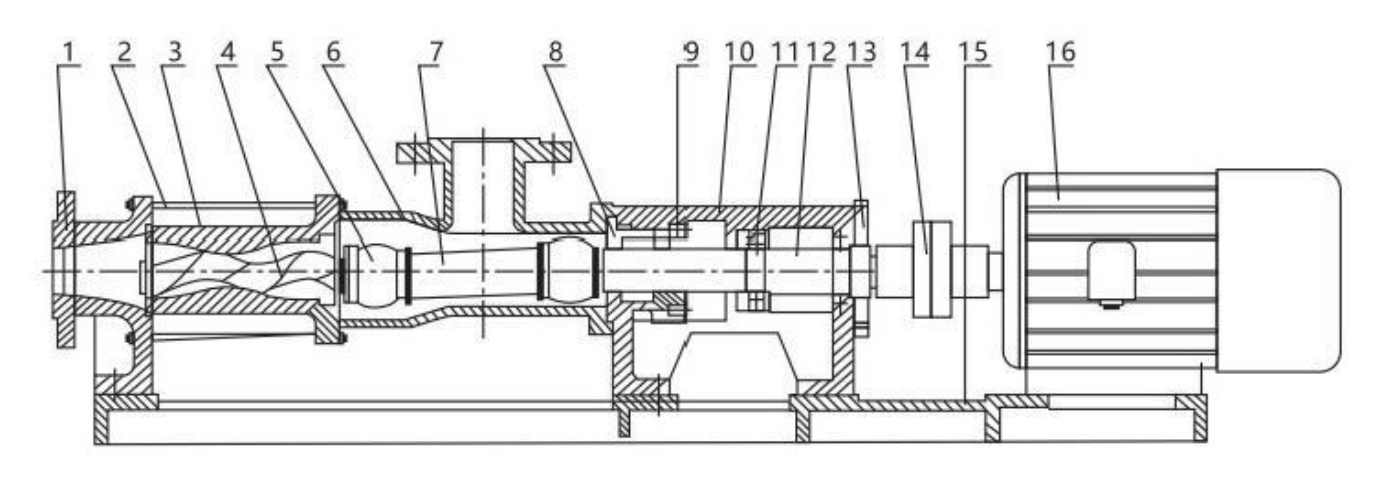

Structural Diagram

| No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 |

| Name | Discharge Body | Tie Rod | Stator | Screw Shaft | Feed Body | Connecting Shaft | Packing Seat | Bearing Seat | Bearing | Drive Shaft | Bearing Cover | Coupling | Base Plate | Motor |

| Model | Flow Rate (m³/h) | Pressure (MPa) | Maximum Allowable Speed (r/min) | Motor Power (kW) | Required NPSH (m) | Inlet Flange Diameter (mm) | Outlet Flange Diameter (mm) | Maximum Allowable Particle Diameter (mm) | Maximum Allowable Fiber Length (mm) |

| G20 - 1 | 0.8 | 0.6 | 960 | 0.75 | 4 | 25 | 25 | 1.5 | 25 |

| G20 - 2 | 0.8 | 1.2 | 960 | 1.5 | 4 | 25 | 25 | 1.5 | 25 |

| G25 - 1 | 2 | 0.6 | 960 | 1.5 | 4 | 32 | 25 | 2 | 30 |

| G25 - 2 | 2 | 1.2 | 960 | 2.2 | 4 | 32 | 25 | 2 | 30 |

| G30 - 1 | 5 | 0.6 | 960 | 2.2 | 4 | 50 | 40 | 2.5 | 35 |

| G30 - 2 | 5 | 1.2 | 960 | 3 | 4 | 50 | 40 | 2.5 | 35 |

| G35 - 1 | 8 | 0.6 | 960 | 3 | 4 | 65 | 50 | 3 | 40 |

| G35 - 2 | 8 | 1.2 | 960 | 4 | 4 | 65 | 50 | 3 | 40 |

| G40 - 1 | 12 | 0.6 | 960 | 4 | 4 | 80 | 65 | 3.8 | 45 |

| G40 - 2 | 12 | 1.2 | 960 | 5.5 | 4 | 80 | 65 | 3.8 | 45 |

| G50 - 1 | 20 | 0.6 | 960 | 5.5 | 4.5 | 100 | 80 | 5 | 50 |

| G50 - 2 | 20 | 1.2 | 960 | 7.5 | 4.5 | 100 | 80 | 5 | 50 |

| G60 - 1 | 30 | 0.6 | 960 | 11 | 5 | 125 | 100 | 6 | 60 |

| G60 - 2 | 30 | 1.2 | 720 | 11 | 5 | 125 | 100 | 6 | 60 |

| G70 - 1 | 45 | 0.6 | 720 | 11 | 5 | 150 | 125 | 8 | 70 |

| G70 - 2 | 45 | 1.2 | 720 | 15 | 5 | 150 | 125 | 8 | 70 |

| G85 - 1 | 60 | 0.6 | 720 | 11 | 5 | 150 | 150 | 10 | 80 |

| G85 - 2 | 60 | 1.2 | 720 | 15 | 5 | 150 | 150 | 10 | 80 |