The CQ Magnetic Drive Pump features a seal-less magnetic coupling design, ideal for safe handling of hazardous, corrosive, or high-purity fluids. Energy-efficient, low-maintenance, and compact, it excels in chemical, pharmaceutical, and food processing applications.

MOQ:

1Package:

CustomziedColor:

CustomziedMaterial:

Stainless Steel

Product Features

The CQ Magnetic Drive Pump integrates permanent magnetic coupling technology into centrifugal pumps,offering a rationally designed,advanced-engineered solution with full sealing,leak-free operation,and corrosion resistance,matching the advanced performance levels of similar foreign products.By replacing dynamic seals with static seals,the pump ensures complete sealing of flow components,eliminating leaks,drips,or spills common in traditional mechanical seals.Constructed from corrosion-resistant,high-strength engineering plastics,alumina ceramics,or stainless steel,it prevents contamination of the transported medium while maintaining durability.

Main Application

Compact in structure, aesthetically designed, lightweight, low-noise, and highly reliable, the CQ Magnetic Pump offers easy maintenance. Ideal for chemical, pharmaceutical, petroleum, electroplating, food, film and photographic processing, scientific research, and national defense industries, it efficiently handles acids, alkalis, oils, rare fluids, toxic liquids, volatile substances, and cooling water systems. Particularly suited for leakage-prone, flammable, or explosive fluids, this pump ensures safety and efficiency.

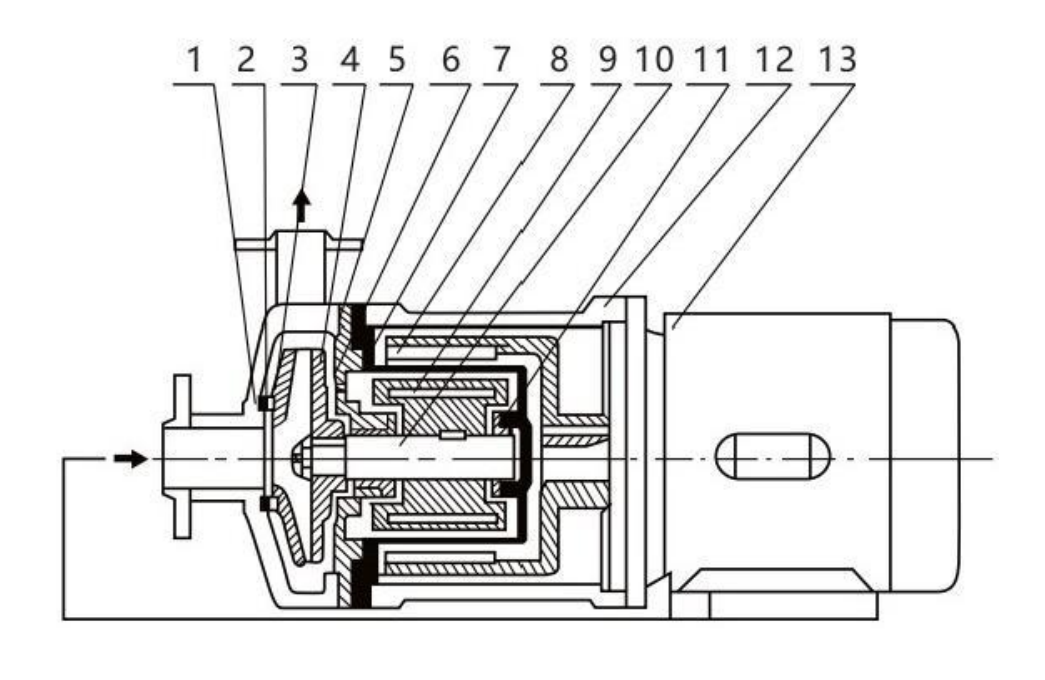

Structural Diagram

| 1 | Pump Casing | 2 | Static Ring |

| 3 | Rotating Ring | 4 | Impeller |

| 5 | Sealing Ring | 6 | Partition Plate |

| 7 | Isolation Sleeve | 8 | Outer Magnet Assembly |

| 9 | Inner Magnet Assembly | 10 | Pump Shaft |

| 11 | Shaft Sleeve | 12 | Connecting Bracket |

| 13 | Motor |

Installation and Use of Magnetic Pumps

(1) The magnetic pump should be installed horizontally and not vertically. The plastic pump body shall not bear the weight of the pipeline. In special cases where vertical installation is required, the motor must face upwards.

(2) When the liquid level being pumped is higher than the pump shaft centerline, just open the valve of the suction pipeline before starting. If the liquid level being pumped is lower than the pump shaft centerline, a foot valve needs to be installed in the pipeline.

(3) Before using the pump, an inspection should be carried out. The fan blades of the motor should rotate flexibly without jamming or abnormal noise, and all fasteners should be tightened.

(4) Check whether the rotation direction of the motor is consistent with the rotation direction mark of the magnetic pump.

(5) After the motor starts, slowly open the discharge valve. After the pump enters the normal working state, adjust the discharge valve to the required opening degree.

(6) Before stopping the pump, first close the discharge valve, and then close the suction pipe valve.