The ISW horizontal centrifugal pump is a single-stage, single-suction design for efficient fluid transfer in pipelines, HVAC, and water supply systems.

MOQ:

1Package:

CustomziedColor:

CustomziedMaterial:

Cast iron/Stainless steelWorking Temp:

≤40℃

Product Overview

The ISW, ISWR, ISWH, ISWY, ISWHY, ISWD, ISWRD, ISWHD, ISWYD, and ISWHYD series horizontal centrifugal pumps are designed based on the performance parameters of IS-type and IR-type centrifugal pumps, in compliance with the ISO 2858 standard. Utilizing advanced domestic hydraulic models and optimized design, these pumps represent an ideal new generation of high-efficiency and energy-saving horizontal pump products.

Operating Conditions

The maximum working pressure of the pump system is 1.6 MPa, meaning the sum of the pump’s suction pressure and head must be less than 1.6 MPa. (If the system pressure exceeds 1.6 MPa, please specify during ordering so that cast steel can be used for the pump's flow-passing and connection components.) The pump is designed to handle clean water or other liquids with similar physical and chemical properties. (If the medium contains fine particles, please specify during ordering to equip wear-resistant mechanical seals.) Ambient temperature should not exceed 40°C, altitude should not exceed 1000 m, and relative humidity should not exceed 95%.

Main Applications

1.ISW Horizontal Clear Water Pump: Designed for conveying clean water and other liquids with similar physical/chemical properties. Suitable for industrial/urban water supply/drainage, high-rise building pressurization, garden irrigation, firefighting boost, long-distance transport, HVAC circulation, bathroom hot/cold water circulation, and equipment matching. Operating temperature: T ≤ 80°C.

2.ISWR/ISWRD Horizontal Hot Water Pump: Widely used for hot water circulation and pressurization in boilers (energy, metallurgy, chemical, textile, papermaking industries, hotels, baths, etc.) and urban heating systems. Operating temperature: T ≤ 120°C.

3.ISWH Horizontal Chemical Pump: Transfers non-solid, corrosive, water-like viscosity liquids. Ideal for petroleum, chemical, metallurgy, power, papermaking, food/pharmaceutical, and synthetic fiber industries. Operating temperature: -20°C ~ +120°C.

4.ISWB Horizontal Pipeline Oil Pump: Transports gasoline, kerosene, diesel, and other flammable/explosive liquids. Operating temperature: +20°C ~ +120°C.

Product Features

1.Compact Structure: The horizontal design integrates the pump and motor into a single unit, offering a sleek appearance and 30% smaller footprint compared to conventional horizontal pumps. With an IP54-rated outdoor motor, it can operate without a pump house, suitable for outdoor installation.

2.Smooth & Quiet Operation: High concentricity ensures stable performance. Direct motor-pump coupling eliminates intermediate components, reducing vibration and noise. The dynamically balanced impeller extends bearing life and improves operational environment.

3.Premium Mechanical Seal: Hard-alloy dynamic/static rings enhance wear resistance, ensuring leak-free operation and extended service life.

4.Advanced Hydraulic Design: Optimized efficiency and superior performance with an innovative impeller model.

5.Unique Structural Details: Features a drainage hole at the pump base and pressure taps on inlet/outlet flanges for easy maintenance and monitoring.

6.Pipe-Friendly Configuration: Horizontal inlet and vertical upward outlet simplify pipeline layout and installation.

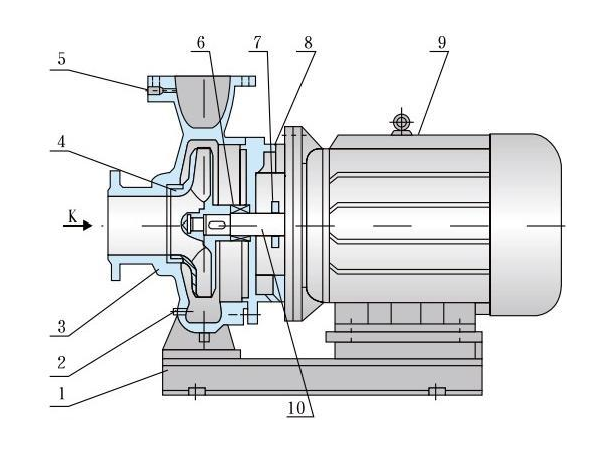

Structural Diagram

| 1 | Base |

| 2 | Drain Hole |

| 3 | Pump Body |

| 4 | Impeller |

| 5 | Pressure Tap |

| 6 | Mechanical Seal |

| 7 | Water Retaining Ring |

| 8 | End Cover |

| 9 | Motor |

| 10 | Shaft |

See Diagram:

The unit consists of three parts: pump, motor, and base. The pump structure comprises the pump body, impeller, pump cover, mechanical seal, and other components. It is a single-stage, single-suction, horizontal centrifugal pump, with the pump body and cover split at the impeller’s rear (rear-halved design).

Most pumps feature seal rings on both front and rear sides of the impeller, along with balance holes on the rear cover to counteract axial thrust on the rotor.

a.Flow Design: Axial horizontal inlet, vertical upward outlet.

b.Shaft Configuration: Pump and motor are co-axial. The motor shaft extension uses double angular contact ball bearings to partially balance residual axial force.

c.Installation: Direct-coupled with no alignment required; shared base with IG-type vibration isolators for reduced vibration.

Others