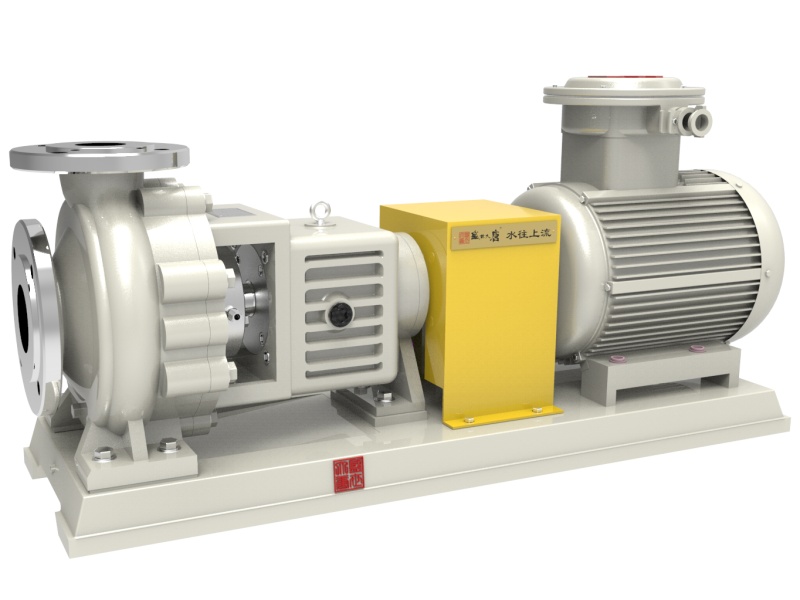

Chemical centrifugal force pump, with simple structure, converts rotational energy into hydrodynamic energy to transport various liquids. Widely used in multiple industries, it is energy-saving, durable, and has a long service life.

MOQ:

1Package:

CustomizedColor:

CustomizedMaterial:

Steel/SICWorking Temp:

-20 to 350℃/ The temperature of the transportable medium is 300 ℃Working Pressure:

1.6 MPa

Product overview

The TI chemical industrial centrifugal pumps are horizontal single stage centrifugal pump capable of transferring corrosive liquids with a viscosity similar to that of water and free of solid particles. Both its rated and designed performance are in accordance with the international standard ISO2858.

This TI chemical industrial centrifugal force pumps are nationally promoted energy-saving product. It has the following design features: a wide performance range, high efficiency, ease of maintenance, strong corrosion resistance, excellent wear resistance, non-toxicity, anti-aging properties, high mechanical strength, a reasonable design, reliable sealing performance, stable operation, and a long service life, among others.

Product advantages

1. The TI chemical industrial centrifugal transfer pumps are independently designed in accordance with international standards such as ISO2858, GB5662, and DIN24256. Its technical indicators and performance have already attained the domestic and international advanced levels of similar products.

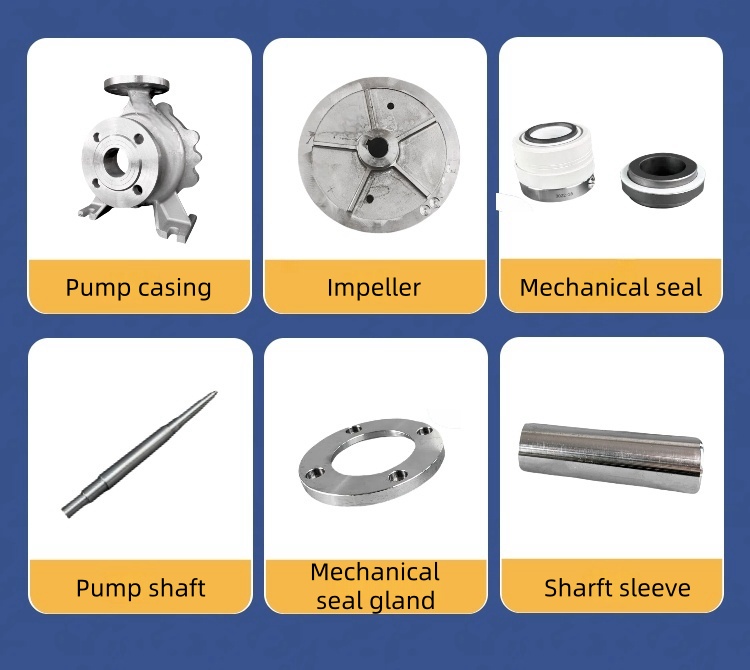

2. The flow-passing components, including the pump body, inner rotor, pump cover, impeller, distance sleeve, etc., are all manufactured from superior stainless steel or special materials.

3. The shaft seal is an built-in single mechanical seal. The optional grinding sealing surfaces include silicon carbide, cemented carbide, etc. Clients can also select a double mechanical seal or an external mechanical seal as required, so as to ensure that the needs of conveying various media and the service life of the shaft seal are met.

4. It is mounted horizontally, featuring a compact structure, low noise, small vibration, small footprint, and stable operation.

Material list

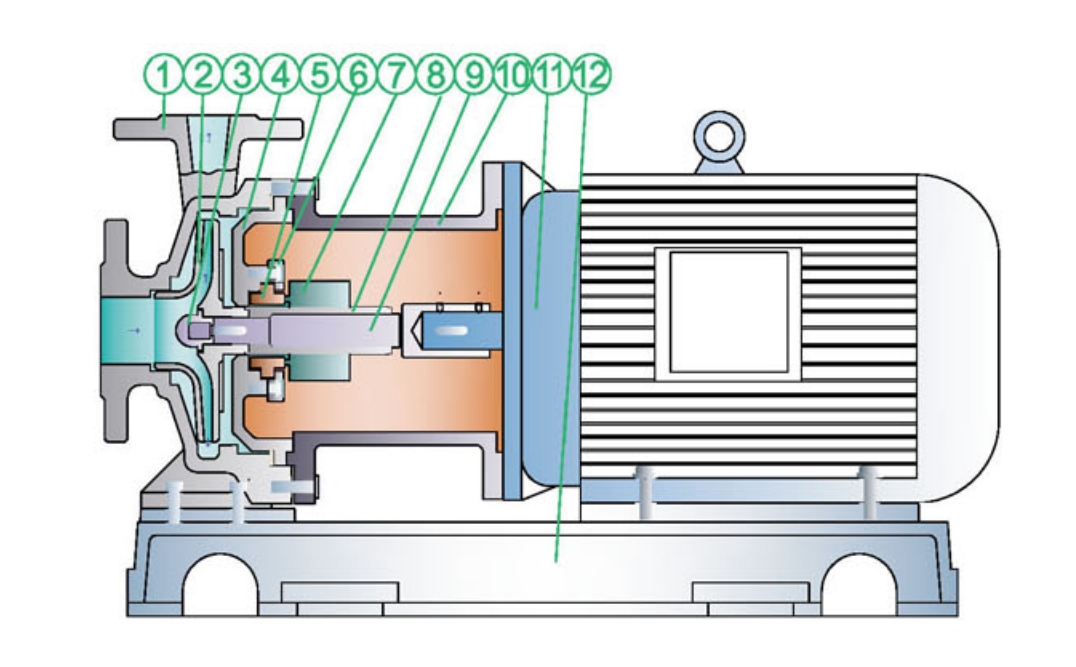

| Part | Material | Part | Material | Part | Material |

| ①Pump casing | 304/316/316L | ⑤Static ring | SIC/HARD ALLOY | ⑨Pump shaft | 304/316/316L |

| ②Impeller | 304/316/316L | ⑥Seal gland | 304/316/316L | ⑩Bracket | HT200 |

| ③Impeller nut | 304/316/316L | ⑦Dynamic ring | SIC/HARD ALLOY | ⑪ Motor | Customized |

| ④Pump cover | 304/316/316L | ⑧Shaft sleeve | 304/316/316L | ⑫ Base plate | HT200 |

Structural diagram

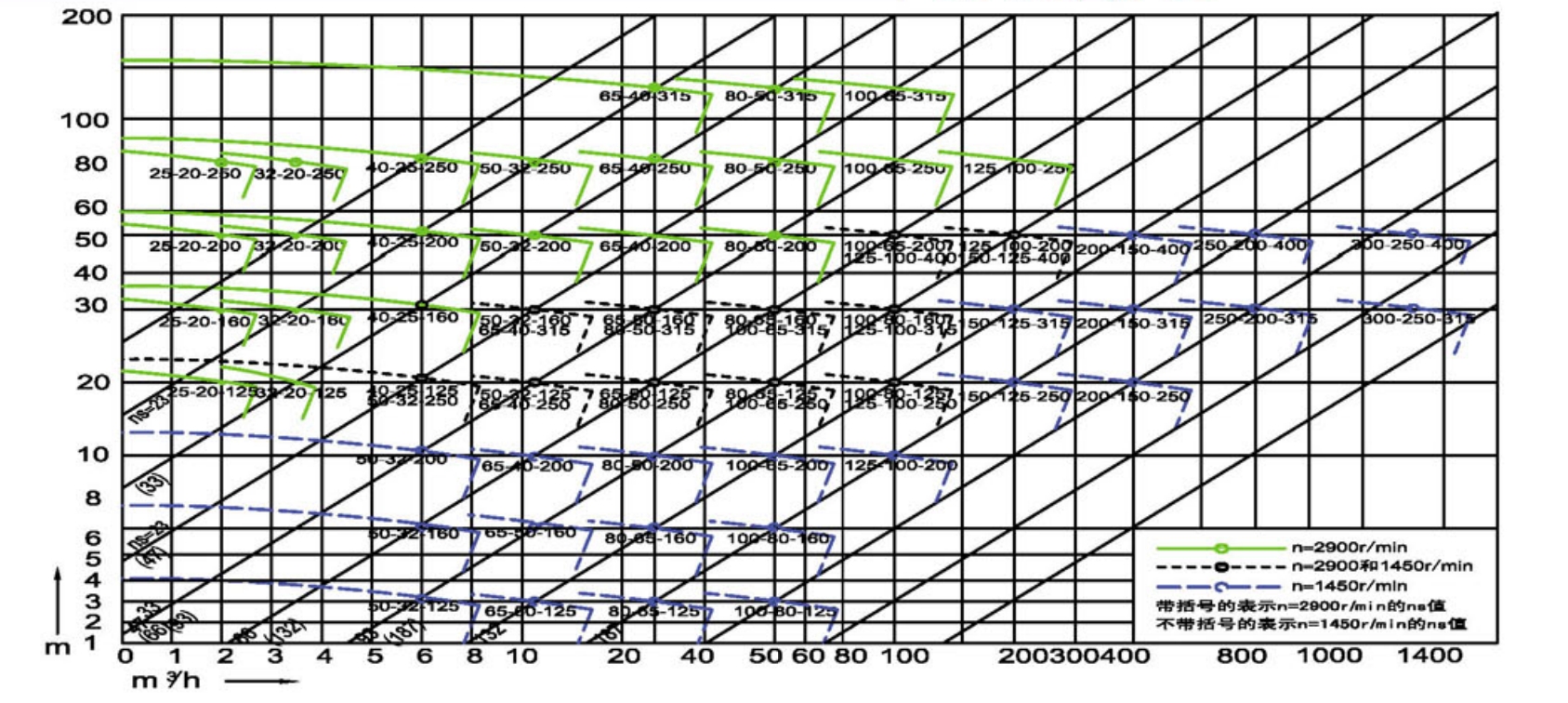

Performance range

Design pressure: 1.6MPa,Flow: 2-1200m³/h,Head: 3-125m, Power: 1.1-200kw.

Applicable temperature: -20~350℃.

NOTES: Please indicate during ordering if the proportion of medium is larger than 1.3mg/cm³. No idling running. No delivering medium with particles or crystalline.

Product application--high temperature centrifugal pump

It widely applied to many fields or processes as high temp centrifugal pump, such as petroleum, chemical, acid, alkali, rare earth, smelting, pesticides, dyes, medicine, paper making, electroplate, electrolysis, acid pickling, radio, formed foil, research organizations and national defense, etc. Particularly be applicable to delivery strong corrosive medium of flammable, explosive, volatile, toxic, strong acid and alkali, organic solvents and other expensive liquids, etc.

Others