The ZXL direct-coupled self-priming centrifugal pump enables efficient, maintenance-free fluid transfer with automatic priming, ideal for industrial and agricultural applications.

MOQ:

1Package:

CustomziedColor:

CustomziedMaterial:

Cast iron/Stainless steel

Product Overview

ZXL Direct-Connected Self-Priming Pump Series is an innovative product developed by our organization through the digestion, absorption and improvement of relevant domestic and international technical data. As a domestic pioneering achievement, it features leading technical performance indicators that reach international advanced levels, demonstrating broad application potential and promising market prospects.

Product Features

The ZXL direct-coupled self-priming pump features a compact horizontal design (30% smaller footprint), vibration-free operation with precision-balanced impeller, wear-resistant tungsten carbide mechanical seals, and advanced hydraulic efficiency. Its innovative structure enables reliable self-priming with minimal initial fluid, while simplified piping (no check/foot valves) ensures easy installation. Ideal for outdoor use with IP54 motor protection.

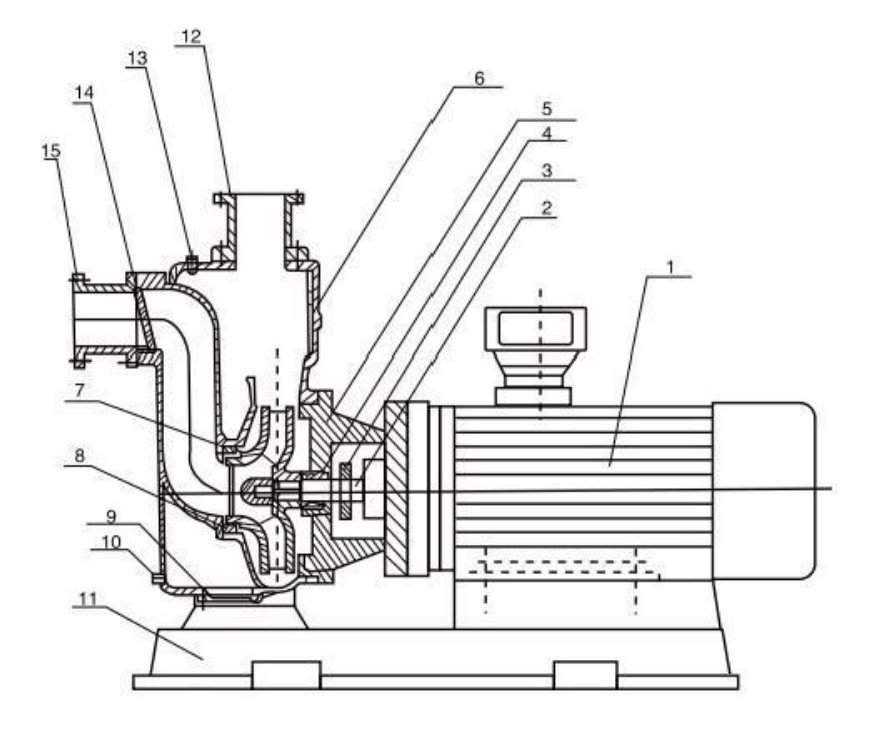

Structural Diagram

| 1 | Motor | Directly coupled to the pump for power transmission. Uses branded motors (CYZ-A-L model adopts explosion-proof motors). |

| 2 | Pump Shaft | Coaxial with the motor. Features an extended shaft design ensuring concentricity for smooth operation (noise/vibration-free). Chrome-plated for enhanced durability. |

| 3 | Water Deflector Ring | Prevents motor flooding due to seal leakage. |

| 4 | Mechanical Seal | Constructed with stainless steel, tungsten carbide, and fluororubber. Balanced high-temperature/pressure-resistant design ensures leak-free operation, zero shaft wear, and no scale buildup. |

| 5 | Pump Cover | Connects the pump body and motor. |

| 6 | Pump Body | Designed with optimized hydraulic chambers (discharge/suction/gas-liquid separation). Features mounting feet for stable installation. |

| 7 | Impeller | High-efficiency hydraulic design for reliable performance. |

| 8 | Seal Ring | Seals the joint between impeller and pump body. |

| 9 | Bottom Cover Plate | Allows sediment removal when opened. |

| 10 | Drain Plug | Drains residual liquid during prolonged pump inactivity. |

| 11 | Baseplate | Provides structural connection and supports vibration isolator installation. |

| 12 | Discharge Nozzle | Connects to outlet pipelines. |

| 13 | Water Fill Valve | Replenishes cavity liquid when insufficient. |

| 14 | Check Valve | Prevents backflow upon pump shutdown. |

| 15 | Inlet Nozzle | Connects to intake pipelines. |

Application scenarios