FY Submersible Pump is a vertical centrifugal pump for conveying particle-laden, corrosive, or high-temperature liquids, featuring submerged operation and long-shaft design.

MOQ:

1Package:

CustomziedColor:

CustomziedWorking Temp:

-20 to 150℃

Product Features

The FY series chemical submersible pumps are vertical single-stage single-suction centrifugal pumps. They are designed for transporting corrosive liquids that do not contain solid particles and are not prone to crystallization. The temperature range of the conveyed medium is -20°C to 150°C, and under special requirements, it can be extended to -50°C to 150°C. The working part of the submersible pump is submerged in the liquid, ensuring no leakage from the shaft seal. Additionally, it features a compact footprint, reliable operation, easy maintenance, and strong corrosion resistance. These pumps are widely used in industries such as chemical engineering and petroleum.

Product Overview

The FY submersible pump is a durable, high-efficiency wastewater solution designed for industrial and municipal use. With corrosion-resistant materials and energy-saving motors, it ensures reliable performance in demanding environments.

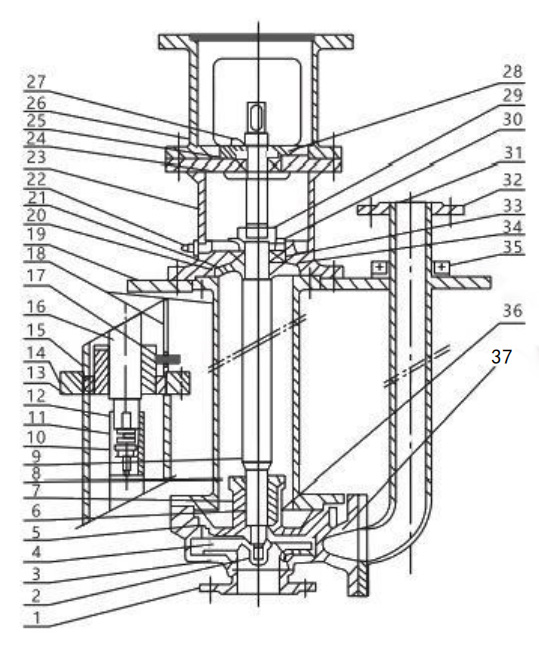

Structural Diagram

| 1 | Pump Body | 20 | Liquid Slinger |

| 2 | Impeller Nut | 21 | Lower Bearing Cover |

| 3 | Impeller | 22 | Grease Cup |

| 4 | Gasket | 23 | Bearing Housing |

| 5 | Pump Cover | 24 | Upper Bearing Retainer |

| 6 | Column Pipe | 25 | Bearing |

| 7 | Guide Bearing | 26 | Motor Base |

| 8 | Guide Bearing Cover | 27 | Grease Cup |

| 9 | Pump Shaft | 28 | Upper Bearing Cover |

| 10 | Drive Sleeve | 29 | Lock Nut |

| 11 | Connecting Sleeve | 30 | Lower Bearing Retainer |

| 12 | Key | 31 | Discharge Pipe |

| 13 | Intermediate Guide Bearing Cover | 32 | Discharge Flange |

| 14 | Intermediate Guide Bearing Housing | 33 | Bearing |

| 15 | Intermediate Guide Bearing | 34 | Oil Seal |

| 16 | Pump Shaft | 35 | Split Flange |

| 17 | Lubrication Pipe | 36 | Key |

| 18 | Column Pipe | 37 | Gasket |

| 19 | Support Pipe | 38 | Lower Bearing Cover |

The FY-type submersible pump primarily consists of components such as the pump body, pump cover, impeller, shaft, flexible coupling, pipe flange, guide bearing, intermediate connecting pipe, discharge pipe, bearing frame, base plate, and motor frame. The pump's suction inlet is aligned along the axial direction, while the outlet is parallel to the axis. When viewed from the suction inlet toward the motor end, the pump rotates clockwise.

The vertical motor of the FY-type pump is securely fastened to the motor base with bolts and transmits power directly to the pump via a flexible coupling. The pump body, intermediate connecting pipe, pump frame, discharge pipe, and pipe flange are bolted together to form a single unit, which is then fixed onto the base plate. The entire pump assembly is mounted on the container via the base plate. Except for key components such as the motor base, pump frame, and base plate—which are made of cast iron—the FY-type pump is constructed with other major parts.

The axial and radial forces acting on the pump (including water pressure generated during operation, as well as the weight of the impeller and rotor) are supported by bearings lubricated with grease. The guide bearing is lubricated by the conveyed liquid. Therefore, the liquid level during operation must remain above the impeller centerline.

The FY-type pump employs a soft packing seal as its primary sealing method, with grease supplied to the packing ring to ensure proper sealing performance and extend service life. It is recommended to add an appropriate amount of molybdenum disulfide to the grease. Additionally, the FY-type corrosion-resistant submersible centrifugal pump series is categorized into two structures based on the immersion length (L) into the container: one with an intermediate guide bearing and the other without.

Others