ZWL Direct-coupled Self-priming Sewage Pump – Efficient, durable, and clog-resistant for wastewater drainage. Ideal for municipal, industrial, and agricultural applications. Low maintenance, high performance.

MOQ:

1Package:

CustomziedColor:

CustomziedMaterial:

Cast iron/Stainless steel

Product Overview

This pump integrates self-priming and non-clogging sewage discharge functions. It adopts an axial reflux external mixing design and features unique structural designs in the pump body and impeller flow channels. It can operate like a standard self-priming clean water pump without requiring a bottom valve or priming water, while also being capable of suction and discharge of liquids containing large solid particles and long-fiber impurities. It is widely suitable for municipal sewage projects, pond aquaculture, and is the ideal impurity pump for handling chemical media in light industry, papermaking, textiles, food processing, chemical engineering, electrical industries, fibers, slurries, and mixed suspensions.

Product Features

The ZWL pump combines self-suction functionality for handling wastewater containing solids and fibers. Its axial reflow design enables fast self-priming without bond valves or manual filling, When connected directly to large flow channels and optimized impedance, the motor ensures powerful operation with low vibration and noise. Built with durable cast iron or corrosion-resistant materials, it is corrosive and chemically resistant to demanding environments. This compact pump is suitable for municipal wastewater, industrial wastewater, Ideal for aquaculture and chemical processing and easy installation and low maintenance ZWL provides reliable fluid transfer that maximizes productivity across a variety of applications and simultaneous operating costs.

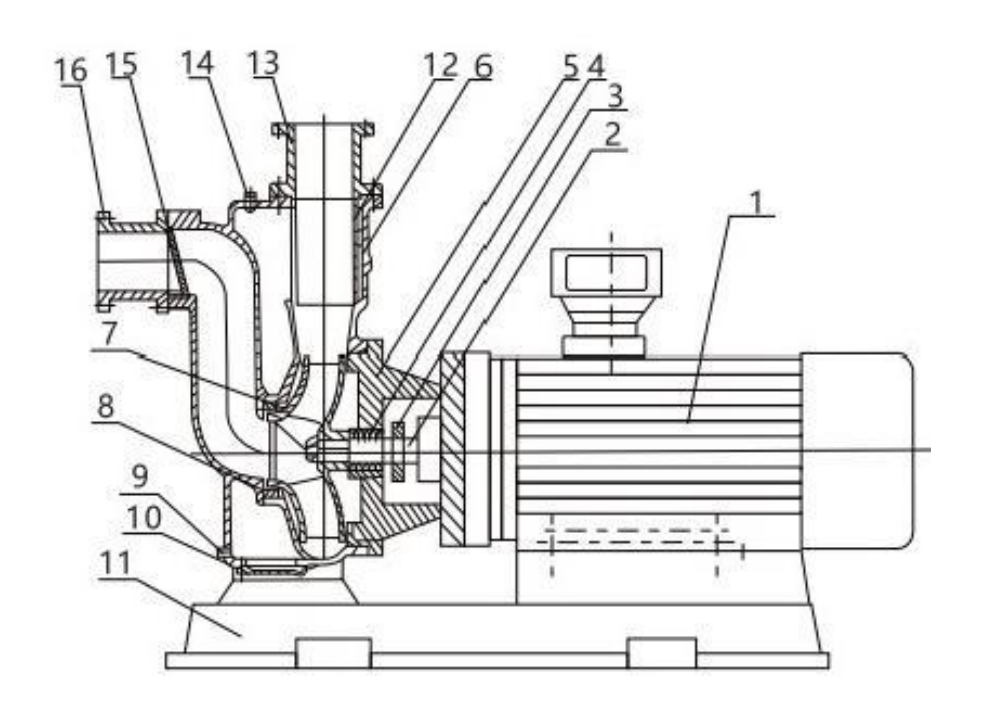

Structural Diagram

| 1 | Motor | Directly connected to the water pump for power transmission, using a branded motor. |

| 2 | Pump Shaft | Coaxial with the motor. It is an extended motor shaft, ensuring concentricity for smooth pump operation, noiseless and vibration-free. Chrome-plated for enhanced durability. |

| 3 | Water Retaining Ring | Prevents water leakage into the motor due to seal failure. |

| 4 | Mechanical Seal | Made of stainless steel, tungsten carbide, fluorine rubber, etc. Balanced design resistant to high temperature and pressure, long service life, leak-free, no shaft wear, no scale buildup, ensuring a clean working environment. |

| 5 | Pump Cover | Connects the pump body and the motor. |

| 6 | Pump Body | Designed with an excellent hydraulic model for the pressure chamber, suction chamber, and gas-liquid separation chamber, combining aesthetics and efficiency. Features mounting feet for easy installation and stable operation. |

| 7 | Impeller | Designed using advanced hydraulic models, typically available in single-channel and dual-channel types, offering high efficiency, excellent flow capacity, and reliability. |

| 8 | Seal Ring | Seals the joint between the pump impeller and the pump body. |

| 9 | Drain Plug | Allows draining of stored liquid when the pump is not in use for extended periods. |

| 10 | Bottom Cover Plate | Can be opened to remove accumulated sediment or debris from the pump body. |

| 11 | Base Plate | Connects the entire pump for easy installation and can also accommodate vibration isolators. |

| 12 | Gas-Liquid Separation Tube | During pump startup, air is expelled through this tube, and water is recirculated to complete the self-priming process. |

| 13 | Outlet Pipe | Connects to the discharge pipeline. |

| 14 | Water Fill Valve | Can be opened to add water when the internal cavity of the pump lacks sufficient liquid. |

| 15 | Check Valve Plate | Prevents backflow of water from the pipeline when the pump stops working. |

| 16 | Inlet Pipe | Connects to the inlet pipeline. |