QW Corrosion-Resistant Metal Submersible Sewage Pump features durable stainless steel construction for superior corrosion resistance. It delivers high-efficiency sewage transfer with large flow capacity, automatic operation, and energy-saving performance. Ideal for industrial and municipal wastewater applications, it offers low noise and minimal maintenance.

MOQ:

1Package:

CustomziedColor:

CustomziedMaterial:

Cast iron/Stainless steelWorking Temp:

≤60℃

Product Features

Large-flow anti-clogging design passes 5x fiber & 50% solid particles of pipe diameter; High-efficiency motor with energy-saving performance; Dual tungsten carbide mechanical seals (8,000+ hours lifespan) ; Compact structure, submerged operation eliminates pump house; Leak sensor in oil chamber for seal failure protection; Optional smart control cabinet for leak/overload/temperature monitoring; Dual-guide rail coupling for easy installation/maintenance; Float switch enables automatic water level control; Overload protection across all working ranges; Water-cooled motor allows dry-run operation; Flexible installation: fixed coupling or portable setup.

Application scenarios

The QW corrosion-resistant submersible sewage pump is ideally suited for diverse applications including industrial wastewater discharge, municipal sewage treatment plants, residential drainage systems, civil defense drainage, and hospital/hotel sewage disposal. It also serves construction sites, municipal projects, mining operations, rural biogas systems, irrigation, and water supply installations, offering reliable performance across various demanding environments.

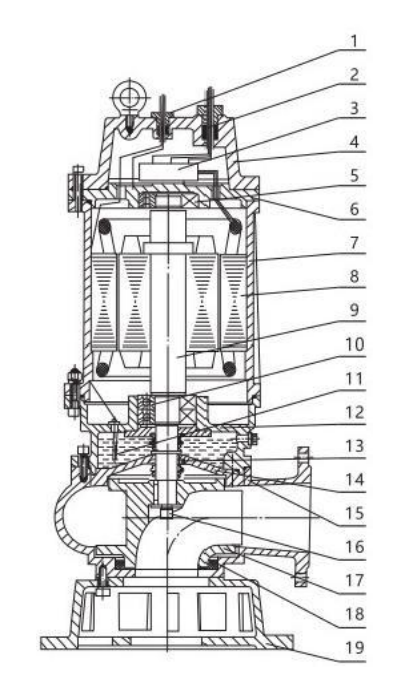

Structural Description

The QW(WQ) series clog-resistant submersible sewage pump integrates motor and pump components, separated by an oil isolation chamber and mechanical seals, forming a compact electromechanical unit with a shared rotor shaft. Key features include:

Signal Cable – Connects to a comprehensive control cabinet for protection against leaks, phase loss, short circuits, overheating, and motor overload.

Stator – Utilizes Class B or F insulation.

Leakage Sensor – Installed in the oil chamber to detect seal failure and trigger system protection.

Mechanical Seal – Dual tandem seals with tungsten carbide for durability and extended service life.

Impeller – Single or double-channel design for superior debris/fiber passage, minimizing clogging.

Pump Casing – Optimized for high efficiency with the impeller.

Wear Ring – Replaceable at the volute to maintain peak efficiency when wear occurs.

| 1 | Signal Wire |

| 2 | Wire Connection |

| 3 | Junction Box |

| 4 | Motor Cover |

| 5 | Bearing |

| 6 | Upper Bearing Housing |

| 7 | Motor Casing |

| 8 | Stator |

| 9 | Shaft (Rotor) |

| 10 | Bearing |

| 11 | Water Leakage Probe |

| 12 | Oil Chamber |

| 13 | Mechanical Seal |

| 14 | Rear Cover Plate |

| 15 | Pump Body |

| 16 | Impeller Bolt |

| 17 | Impeller |

| 18 | Seal Ring |

| 19 | Base Plate |

Operating Conditions

1.Medium temperature ≤60°C, specific gravity 1.0-1.3kg/dm³, pH 5-9.

2.For pumps without internal cooling systems, ≤50% of the motor may extend above liquid level.

3.Operate within specified head range to prevent motor overload. For full-range operation, special order required.

4.Running current must not exceed motor's rated current.