The TCD no-leakage multistage magnetic pump, featuring a multistage structure, is capable of generating high pressure. Its magnetic coupling ensures leak-free operation, making it an excellent option for precise fluid handling in a wide range of fields.

Payment:

TT L/C PayPal Westunion MoneygramProduct Origin:

China, Anhui provinceColor:

customizedShipping Port:

shanghaiLead Time:

1 monthMOQ:

1Package:

CustomziedColor:

CustomziedMaterial:

SteelWorking Temp:

-60 to 300 ℃,New material withstands temperatures up to 450°CWorking Pressure:

1.6 to 6.3 MPa

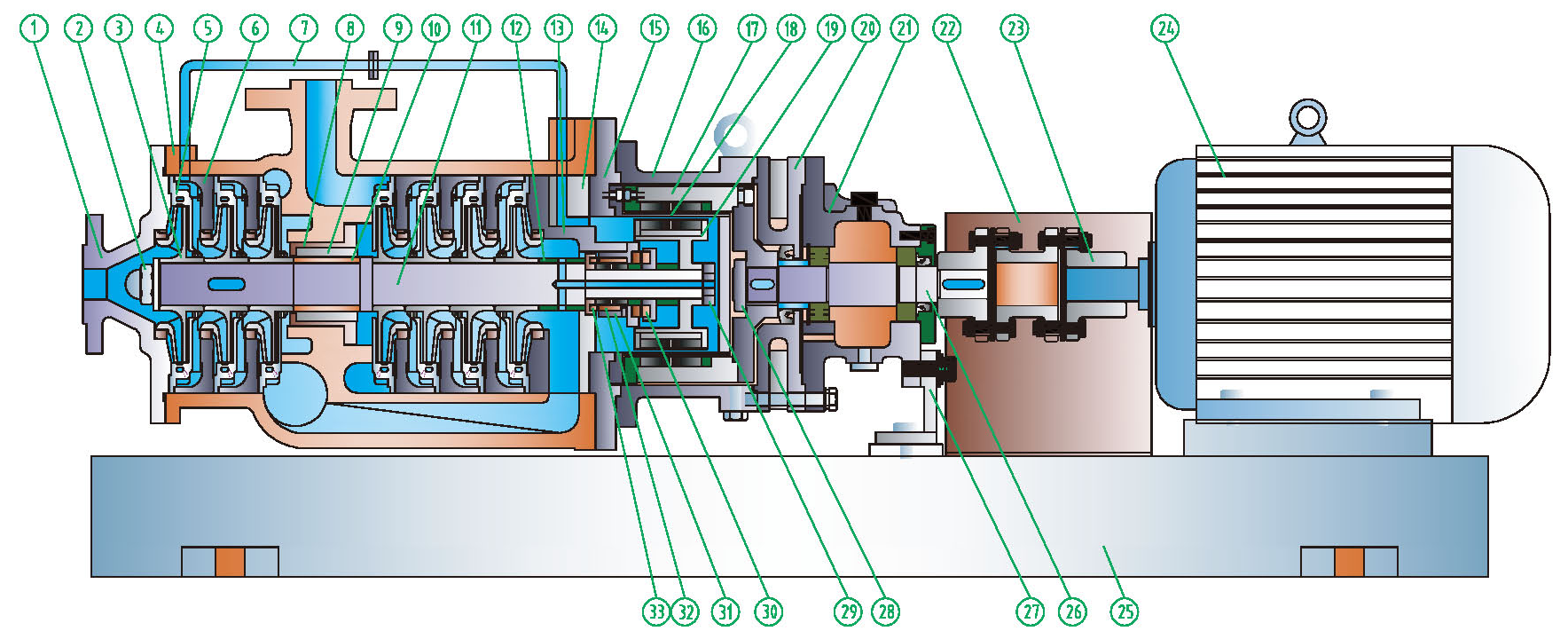

Product overview

Our company has designed the TCD leak-free multistage magnetic pump (horizontal multistage centrifugal pump) to address the challenge of fluid transportation involving small flow rates and high heads. The design of its structure, hydraulic system, and magnetic circuit incorporates advanced and innovative technologies. Moreover, the magnetic drive technology has been successfully implemented in the multistage magnetic centrifugal pump. This achievement effectively resolves the issues of axial force balance and static sealing in multistage pumps under conditions of high power, large-gap magnetic circuit design, and high working pressure.

Material List

| Part | Material | Part | Material | Part | Material |

| ① Front cover | 304/316/316L | ⑫ Baffle sleeve | 304/316/316L | ㉓ Coupling | HT200 |

| ② Impeller nut | 304/316/316L | ⑬ Middle cover plate | 304/316/316L | ㉔ Motor | Per clients requested |

| ③ Impeller | 304/316/316L | ⑭ Back cover plate | 304/316/316L | ㉕ Base plate | HT200 |

| ④ Pump body | 304/316/316L | ⑮ Middle flange | 304/316/316L | ㉖ Drive shaft | 2CR13 |

| ⑤ Guide vane | 304/316/316L | ⑯ Bracket | HT200 | ㉗ Bracket plate | HT200 |

| ⑥ Middle | 304/316/316L | ⑰ Outer magnet component | Permenant magnet/ZG | ㉘ Round nut | 45 |

| ⑦ Return line | 304/316/316L | ⑱ Distance sleeve | 316/316L | ㉙ Rotor nut | 304/316/316L |

| ⑧ Front bearing seat | 304/316/316L | ⑲ Rotor component |

Permenant magnet /304/316/316L |

㉚ Back thrust collar | SSIC/hard alloy |

| ⑨ Front bearing | SSIC/hard alloy | ⑳ Bracket | 45 | ㉛ Back bearing | SSIC/hard alloy |

| ⑩ Front bearing sleeve | SSIC/hard alloy | ㉑ Bearing box | HT200 | ㉜ Back bearing sleeve | SSIC/hard alloy |

| ⑪ Pump shaft | 304/316/316L | ㉒ Shield | 202 | ㉝ Front thrust collar | SSIC/hard alloy |

Structural diagram

Performance range

Design pressure :1.6~6.3MPa, Flow :3~155m³/h, Lift :20~603m, Power :5.5~315KW.

Applicable temperature :-60~300℃, new materials are adopted , and the temperature resistance can reach 450℃.

Product application

It is extensively utilized in various production processes such as those in the petroleum industry, chemical industry, acid production, alkali production, smelting, rare earth processing, pesticide manufacturing, dye production, pharmaceuticals, papermaking, electroplating, electrolysis, pickling, etc., for the transportation of corrosive liquids.

Others