QBK Leak-Free Pneumatic Diaphragm Pump: Compact, corrosion-resistant, energy-efficient, ideal for chemical transfer. Zero leakage, low maintenance, durable for harsh environments.

Payment:

TT L/C PayPal Westunion MoneygramProduct Origin:

China, Anhui provinceColor:

customizedShipping Port:

shanghaiLead Time:

1 monthMOQ:

1Package:

CustomziedColor:

CustomziedMaterial:

Cast iron/Stainless steel/Fluorine-linedWorking Temp:

-30 to 180 ℃Working Pressure:

2.5 MPa

Product Overview

The QBK pneumatic diaphragm pump can transport both free-flowing and viscous fluids, offering the combined benefits of self-priming, submersible, canned motor, slurry, and trash pumps with no need for priming (7m suction lift, 70m head, ≥6kgf/cm² outlet pressure), a wide flow path for 10mm solids with minimal wear, adjustable flow/head via air valve (1-7kgf/cm²), leak-free operation for hazardous chemicals, explosion-proof air operation, submersible capability, automatic dry-run/overload protection, low maintenance with no media contact to moving parts, 10,000 cP viscosity handling, and lubrication-free durability even during dry running, making it ideal for tough industrial applications.

Main Applications

The QBK pneumatic diaphragm pump is widely used for handling food products (peanut butter, pickles, mashed potatoes, sausages, chocolate, hops, syrup), paints and adhesives, ceramic glazes, abrasives and corrosive agents, toxic/flammable liquids, wastewater and cement grout, strong acids/alkalis, and as a pre-pressure feeding device for solid-liquid separation systems.

Working Principle

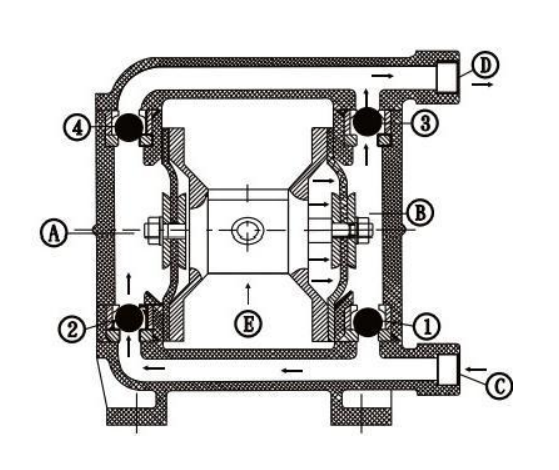

The QBK pneumatic diaphragm pump features two symmetrical working chambers (A and B), each equipped with a diaphragm connected by a central linkage. Compressed air enters through the intake port and is directed by an air distribution valve into one chamber, forcing its diaphragm to move while expelling air from the opposite chamber. At the end of each stroke, the valve automatically switches airflow to the other chamber, reversing diaphragm movement and creating continuous, synchronized reciprocation.

In operation:

1.Air enters the distribution valve (port ⑤), pushing the right diaphragm outward.

2.Chamber A generates suction, drawing media through inlet ③—opening ball valve ② to fill chamber ④ while valve ④ closes.

3.Simultaneously, chamber B compresses media, forcing it through outlet ① via ball valve ③ (ball valve ① closes to prevent backflow).

4.This cycle repeats, enabling continuous suction at inlet ③ and discharge at outlet ①.

Others