Dual Solution for Corrosion-Resistant Chemical Pumps: Synergistic Advantages of Fluoroplastic and Stainless Steel Centrifugal Pumps

In the field of chemical fluid transportation, fluoroplastic and stainless steel centrifugal pumps complement each other's strengths, providing an efficient solution for handling corrosive media. Fluoroplastic pumps offer exceptional chemical inertness, while stainless steel pumps excel in mechanical strength and cost-effectiveness. Together, they address over 95% of industrial corrosion challenges.

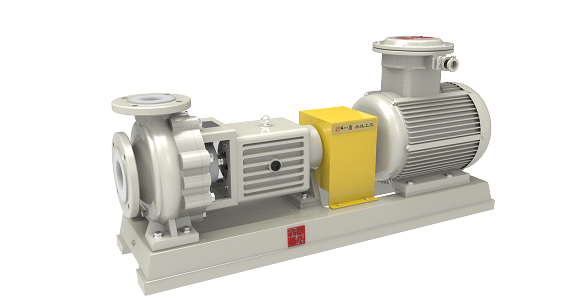

Fluoroplastic centrifugal pumps feature a fully fluoropolymer-lined interior, achieving the highest corrosion resistance rating (5 stars). They are particularly suitable for strong acids, alkalis, and organic solvents, though their pressure-bearing capacity is relatively lower. Stainless steel pumps (e.g., 316L) demonstrate excellent corrosion resistance (4 stars) against weak acids and saline solutions, along with high mechanical strength and pressure tolerance. In Shengshi Datang’s product line, the durable corrosion resistant chemical centrifugal pump and standard chemical industry fluoroplastic centrifugal pump can serve as alternatives.

For example, a chemical plant in Thailand adopted fluoroplastic pumps for 98% concentrated sulfuric acid transfer, paired with 316L stainless steel pumps for brine circulation, reducing equipment costs by 30% while achieving a service life exceeding five years.

Tailored solutions for regional needs:

Russia and CIS markets: Fluoroplastic pumps withstand extreme low temperatures (-60°C to 120°C), while stainless steel pumps are equipped with steam tracing for freeze protection.

Southeast Asia: Fluoroplastic pumps are ideal for precision chemical delivery in electronics factories, while stainless steel pumps perform reliably in seawater desalination systems.

Maintenance recommendations:

For fluoroplastic pumps, prevent wear from solid particles and regularly inspect lining thickness.

For stainless steel pumps, upgrade to duplex steel if chloride ion concentration exceeds 25 ppm.

In hybrid systems, fluoroplastic pumps are suitable for initial processing, while stainless steel pumps are recommended for final pressurization.